What is cell Culture?

Cell culture is the process of growing cells in a controlled environment outside of their natural context. This is done by removing cells from animal or plant tissue, breaking them apart, and cultivating them in an artificial environment. Cell culture is used to study the behaviour and characteristics of cells, and is an important tool in fields such as medicine, genetics, and biotechnology.

Limiting Factors with Scaled up Cell culture

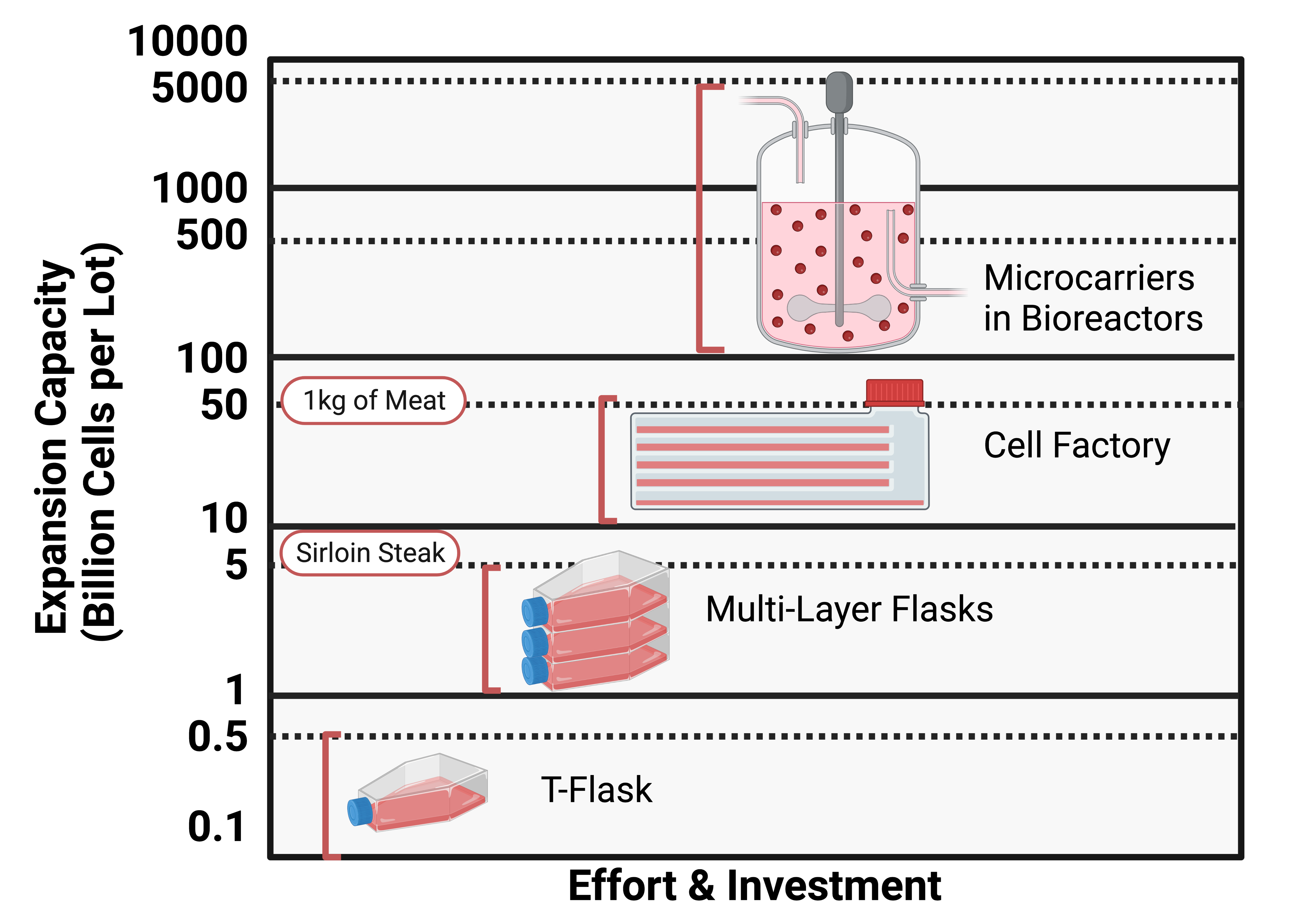

Scaling up cell culture can be challenging due to the limited surface area for cell growth. Traditional small-scale methods, such as plastic flasks, become impractical when attempting to grow cells on a large scale. Technologies like multi-layer flasks and cell factories can improve the surface area-to-volume ratio, but they are not scalable solutions. Bioreactors, which are large stirring tanks, offer a more efficient and automated solution for cell culture. However, these are not suitable for growing cells that require a substrate, such as adherent cells. To overcome this limitation, microcarriers have been developed to allow the growth of these types of cells in suspension in a bioreactor. Despite the challenges, advances in technology and research are helping to mitigate limitations and enable successful large-scale cell culture.

Microcarrier

Microcarriers are small, spherical support matrices that allow for the growth of adherent cells in bioreactors. By culturing cells on the surface of these microcarriers, each particle carries several hundred cells, which greatly increases the expansion capacity of the culture system. This makes microcarriers a valuable tool for scaling up culture systems for industrial production of cell or protein-based therapies, or for research purposes. They provide a simple and efficient way to grow large numbers of cells in a controlled, suspended environment, making them an important innovation in the field of cell culture.

Cultured Meat & Issues with microcarriers

The cultivated meat industry has increased demand for microcarriers, but current options have significant limitations. These limitations include high cost, typically over $2,000 per kg of meat, high cell loss rates of over 50%, and lack of edibility, as microcarriers may be made of non-food grade materials like plastic or glass, which can lead to particulates ending up in the final product. These limitations make current microcarriers unsuitable for the cultivated meat industry and require the development of new solutions that are cost-effective, efficient, and safe for consumption.