Cultivated meat, also referred to as cultured meat, is a form of meat that is produced by growing animal cells in a laboratory setting. This method of production eliminates the need to raise and farm animals for food. The resulting product is made of the same cell types and arranged in a similar structure as conventional meat, thus replicating the sensory and nutritional characteristics of traditional meat. The first cultivated meat burger was presented in 2013 by Dutch scientist Mark Post and since then, the industry has grown to over 60 companies and attracted over $450 million in investments. These companies are working to develop technology solutions and conduct research in fields such as cell culture, stem cell biology, tissue engineering, fermentation, and chemical and bioprocess engineering to establish a new paradigm for manufacturing commodity meat products at industrial scales.

Cultivated meat is considered a promising solution to address the environmental and ethical concerns associated with conventional animal agriculture. It can potentially reduce land, water, and other resources required for farming while reducing greenhouse gas emissions and animal welfare issues. Additionally, cultivated meat could help meet the rising demand for meat globally, especially in countries with growing populations and increasing wealth.

However, several challenges still need to be addressed before cultivated meat can be produced on a large scale and made available to consumers. These include the cost of producing cultivated meat, which is currently much higher than conventional meat, as well as the development of scalable and efficient cell cultivation methods and the creation of a regulatory framework for producing and selling cultivated meat.

Despite these challenges, many experts believe that cultivated meat will play a significant role in the future of food production. Companies and research institutions are investing in this field and making progress towards commercialising cultivated meat products. It is expected that in the coming years, we will see more cultivated meat products becoming available in the market. With further research and development, the cost of producing cultivated meat will decrease and become more accessible to consumers.

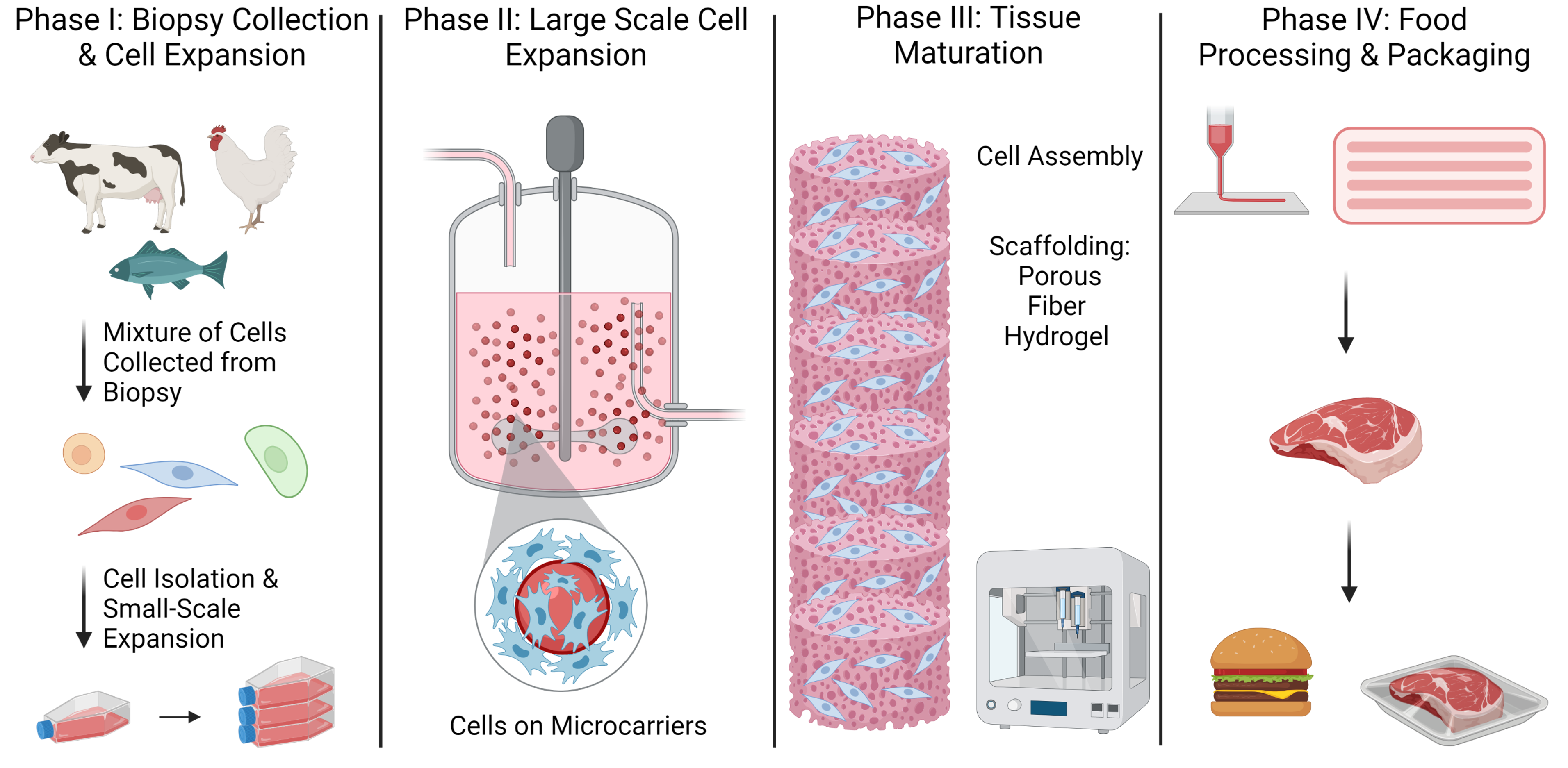

Cultivated Meat Work flow

Phase 1 – Biopsy Collection and Cell Expansion: This is the starting point of the cultivated meat production process. A small biopsy sample is collected from the animal from which the cells will be taken. These cells are then expanded using microcarrier technology, which allows for the growth of large numbers of cells in a small amount of space. This is done by culturing the cells on the surface of spherical microcarriers, which can support several hundred cells per particle, allowing for the expansion of the culture system.

Phase 2 – Large Scale Cell Expansion: Once a sufficient number of cells have been obtained from the initial biopsy, they are expanded on a large scale. This is typically done using bioreactors, large tanks that can support the growth of large numbers of cells in a controlled environment.

Phase 3 – Tissue Maturation: In this phase, the cells are differentiated and matured into a form that closely resembles animal tissue structure. This is done by introducing the cells to a scaffold or a porous, fibrous, or hydrogel matrix, which mimics the structure of the animal tissue and helps guide the cells to form the desired structure.

Phase 4 – Food Processing and Packaging: Once the cells have been differentiated and matured into the desired structure, they are processed into food products. This typically involves mixing the cells with other ingredients, such as plant-based proteins and flavourings, to create a product that resembles traditional meat. The final product is then packaged and stored for distribution.