Microcarrier culture is a powerful tool for large-scale cell production, but it requires careful attention to detail to avoid common mistakes that can compromise the quality and efficiency of your culture. From seeding to harvesting, each step presents its own challenges that, if not managed properly, can lead to suboptimal results.

- Inconsistent Seeding Due to Poor Mixing: Failing to achieve homogenous mixing can lead to uneven distribution of cells across microcarriers, resulting in inconsistent culture growth.2. Insufficient Seeding Density: Under-seeding can cause suboptimal cell coverage on microcarriers, leading to slower growth and reduced culture efficiency.3. Excessive Culture Dilution: Over-diluting the culture lowers the cell-to-microcarrier ratio, hindering efficient cell attachment and growth.4. Skipping Equilibration of Culture Environment: Failing to pre-equilibrate microcarrier beads by soaking them in media and not pre-warming the stir flask before seeding can disrupt cell attachment, increase cellular stress, and ultimately lead to suboptimal growth.

5. Incorrect Microcarrier Concentration: Using too many or too few microcarriers per mL can disrupt the balance needed for optimal cell growth and interaction.6. Overly Fast Stirring Speed: Stirring the culture too quickly can create shear stress, damaging cells and microcarriers, which negatively impacts culture productivity.7. Lack of Non-Adherent Coating in Well Plates: Without a non-adherent coating, cells may attach to the plate surface rather than the microcarriers, reducing effective seeding.8. Premature Stirring: Starting the stirring process too soon can disrupt cell attachment to the microcarriers, leading to poor culture outcomes.9. Inadequate Growth Monitoring: Failing to regularly monitor cell growth can result in unnoticed issues like overgrowth, nutrient depletion, or contamination.10. Improper Timing of Media Changes: Changing the media too frequently or infrequently can either strip away necessary growth factors or lead to nutrient depletion, disrupting cell growth.11. Excessive Enzymatic Treatment: Overexposure to enzymes during the harvesting process can lead to cell membrane damage, reducing cell viability.12. Incomplete Cell Detachment: During harvesting, if cells are not fully detached from the microcarriers, this can lead to significant cell loss and reduce the overall yield. It’s crucial to ensure that the detachment process is thorough, whether using enzymatic or mechanical methods.

5. Incorrect Microcarrier Concentration: Using too many or too few microcarriers per mL can disrupt the balance needed for optimal cell growth and interaction.6. Overly Fast Stirring Speed: Stirring the culture too quickly can create shear stress, damaging cells and microcarriers, which negatively impacts culture productivity.7. Lack of Non-Adherent Coating in Well Plates: Without a non-adherent coating, cells may attach to the plate surface rather than the microcarriers, reducing effective seeding.8. Premature Stirring: Starting the stirring process too soon can disrupt cell attachment to the microcarriers, leading to poor culture outcomes.9. Inadequate Growth Monitoring: Failing to regularly monitor cell growth can result in unnoticed issues like overgrowth, nutrient depletion, or contamination.10. Improper Timing of Media Changes: Changing the media too frequently or infrequently can either strip away necessary growth factors or lead to nutrient depletion, disrupting cell growth.11. Excessive Enzymatic Treatment: Overexposure to enzymes during the harvesting process can lead to cell membrane damage, reducing cell viability.12. Incomplete Cell Detachment: During harvesting, if cells are not fully detached from the microcarriers, this can lead to significant cell loss and reduce the overall yield. It’s crucial to ensure that the detachment process is thorough, whether using enzymatic or mechanical methods.

Successfully navigating these challenges is key to optimizing your microcarrier culture and achieving consistent, high-quality results. If you’re looking to upscale your cell cultivation in an efficient way, get in touch with Smart MCs. Explore our product suite to assist you in large-scale manufacturing and take your bioprocessing to the next level.

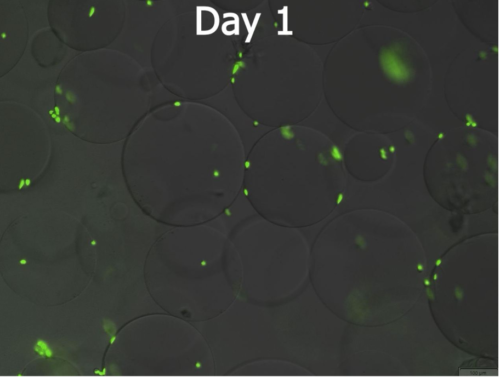

Leave A Comment