A new study led by Shiina Pasanen and colleagues, published in the Biotechnology Journal (2025), demonstrates a powerful approach to expanding human mesenchymal stem cells (hMSCs) using microcarrier-based systems. Although the team used custom-engineered microcarriers, the results strongly support the broader use of microcarriers in regenerative medicine and scalable cell manufacturing.

The Challenge: Scaling Up Stem Cells for Therapy

Human mesenchymal stem cells can differentiate into bone, cartilage, or fat — making them promising for treating injuries and degenerative diseases. However, producing sufficient numbers for therapeutic use remains a bottleneck. Traditional flat culture systems like flasks don’t offer the scalability or efficiency needed.

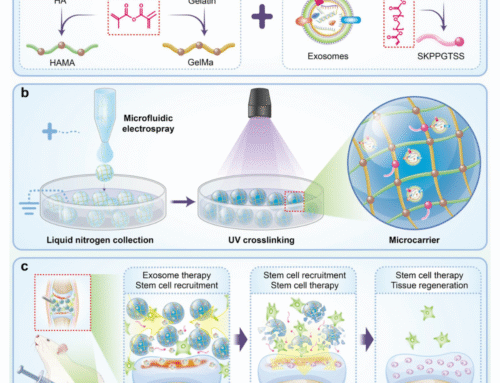

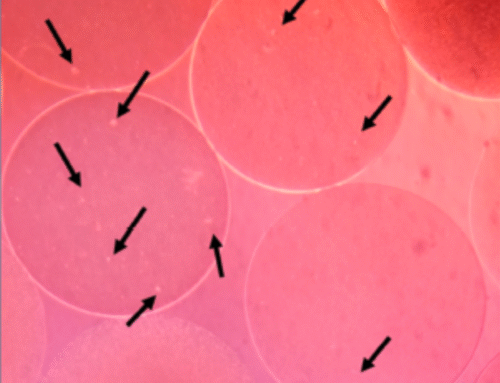

Microcarriers offer a solution: small, floating beads that increase available surface area for cell growth in stirred bioreactors — enabling high-density, scalable expansion.

What the Researchers Did

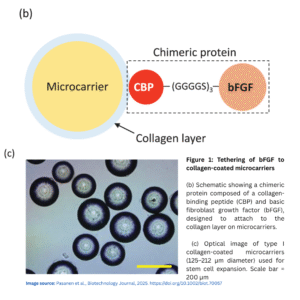

The team developed collagen-coated microcarriers and immobilized a key growth factor, basic fibroblast growth factor (bFGF), on their surface using a collagen-binding peptide (CBP). This helped anchor bFGF to the microcarrier, preventing it from diffusing away in the culture media.

What is bFGF?

bFGF is a natural protein that tells stem cells to grow and divide. It also helps maintain their “stemness,” meaning they don’t age or lose their ability to turn into different cell types.

To keep bFGF attached to the microcarrier surface, the researchers added a collagen-binding peptide (CBP)—a short amino acid sequence that sticks to collagen.

What is a Collagen-Binding Peptide (CBP)?

CBPs are sticky protein tags that naturally attach to collagen (the same protein found in skin and bones). By attaching a CBP to bFGF, the researchers ensured that the growth factor stayed on the microcarrier’s collagen coating, instead of floating away in the liquid media.

Key Results

- Microcarriers with CBP1-bFGF increased hMSC numbers by 13.6× in just 7 days

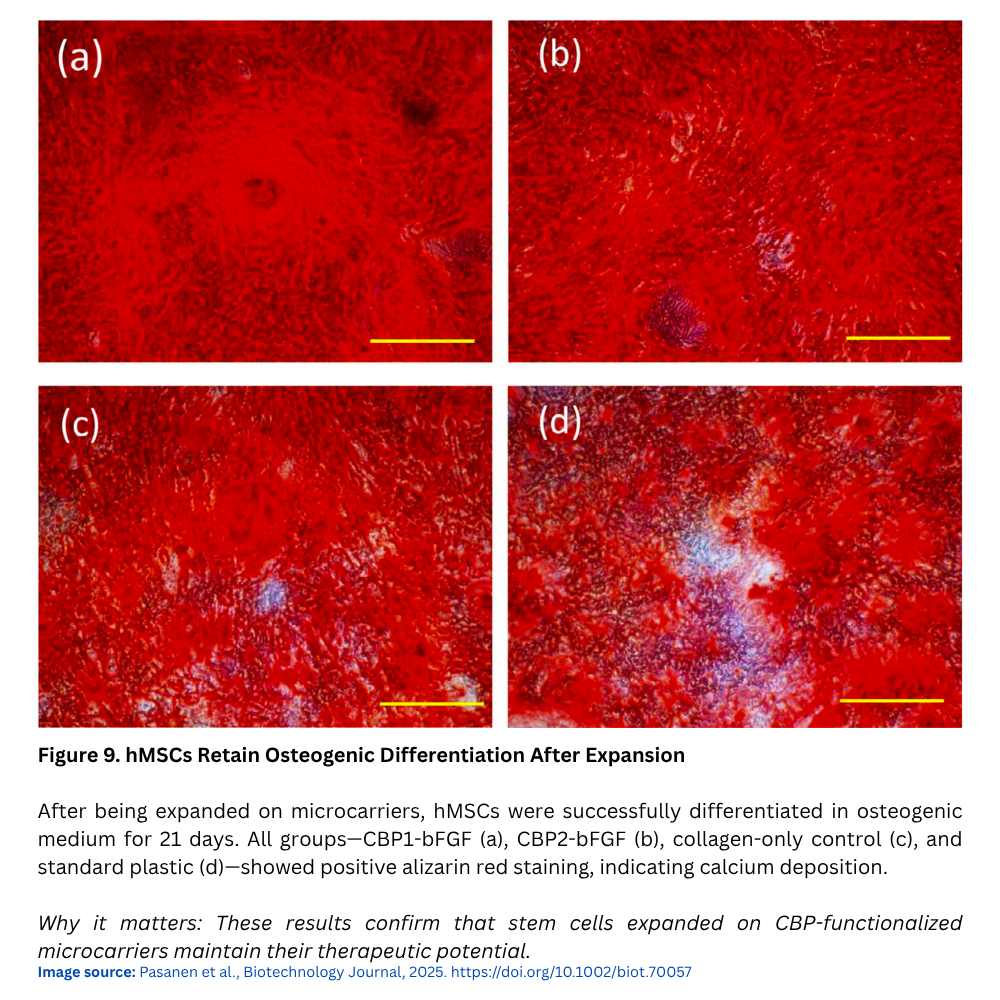

- Cells retained their ability to differentiate into bone (osteogenic potential)

- Nearly 2× more cells than standard collagen-only carriers

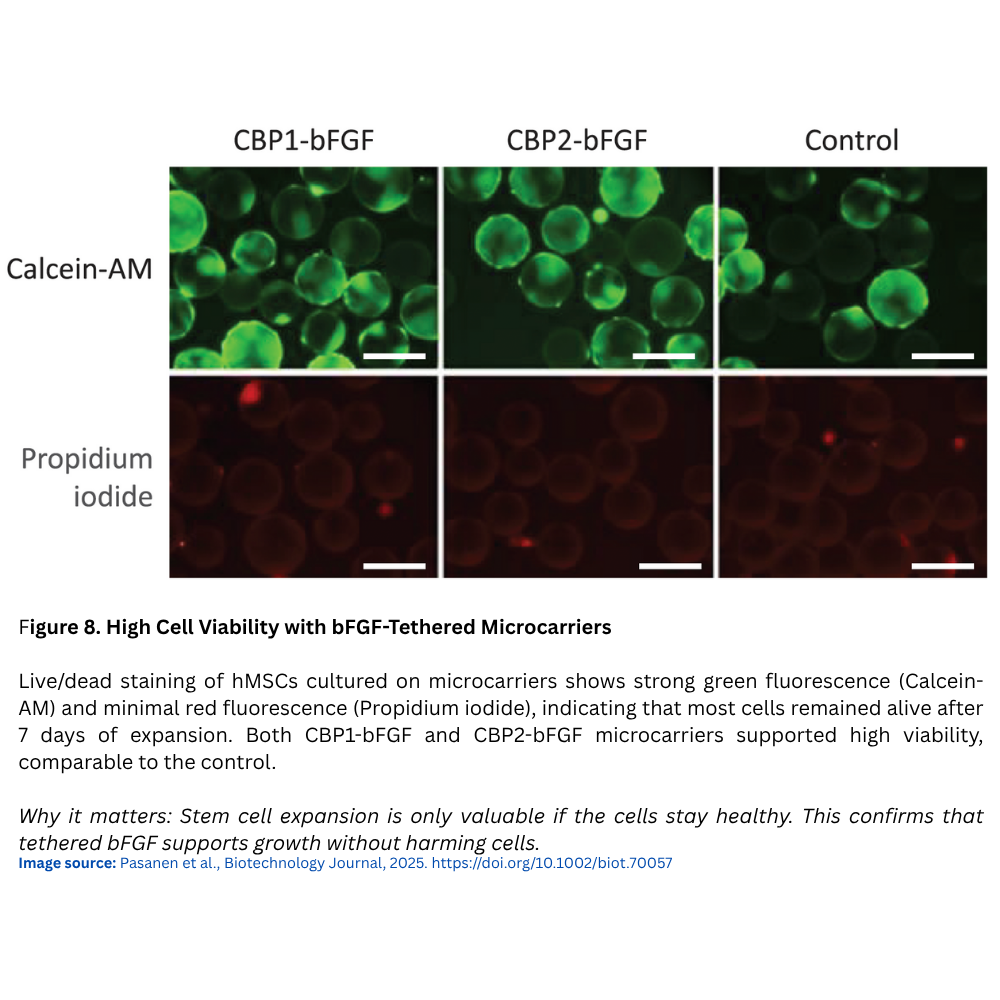

- No signs of toxicity or phenotypic drift during culture

These findings show that well-designed microcarriers can significantly enhance cell yields while maintaining quality, a major step forward for clinical-scale stem cell production.

Why Microcarriers Are Important

Microcarriers allow adherent cells (like stem cells) to grow in 3D culture systems, such as bioreactors. This approach:

- Increased surface area per volume

- Improves nutrient and oxygen distribution

- Compatibility with GMP workflows

- Seamless integration into scalable, automated systemsThis study reinforces the value of combining surface coatings and bioactive cues to boost cell expansion.

Takeaways for Researchers and Process Developers

If you’re working in stem cell therapy, tissue engineering, or bioprocessing, this paper provides a model approach:

Use collagen to support robust adhesion

Add growth factors like bFGF to drive expansion

Use CBPs or anchoring domains to retain bioactivity on the surface

“Microcarriers with collagen-binding bFGF, preferably CBP1-bFGF, are useful substrates for constructing a bioreactor system for hMSC expansion.”

— Pasanen et al., Biotechnology Journal (2025)

Supporting Your Microcarrier Strategy

Whether you’re scaling up stem cell production or exploring microcarrier-based systems for the first time, choosing the right microcarrier platform can directly impact your results. Our microcarriers are engineered for flexibility and high performance, and can be customized to meet specific cell culture requirements.

We offer:

- Collagen-coated microcarriers to support adhesion and growth of sensitive cell types like hMSCs

- Surface charge modifications to improve cell attachment, spreading, and performance in different media environments

- Custom coatings (e.g., fibronectin, laminin, vitronectin, or synthetic polymers) to match your protocol or cell type

- Compatibility with spinner flasks, stirred-tank bioreactors, and automated platforms

Whether your goal is basic research, GMP-ready cell therapy manufacturing, or bioprocess development, we can help tailor a microcarrier solution that supports your workflow and scale.

Contact our team to discuss your application, or you may check out our product page to learn more and get a quote.

Leave A Comment