In a recent publication, researchers have made significant advancements in the scalable production of viral vectors for SARS-CoV-2 vaccines. By leveraging microcarrier-based cell culture in stirred-tank bioreactors, this method offers an efficient and cost-effective solution for lab-based vaccine production. These innovations are essential for addressing the urgent need for rapid vaccine development, particularly during global health crises like the COVID-19 pandemic.

Microcarrier-Based Cultures: A Game Changer for SARS-CoV-2 Vaccine Manufacturing

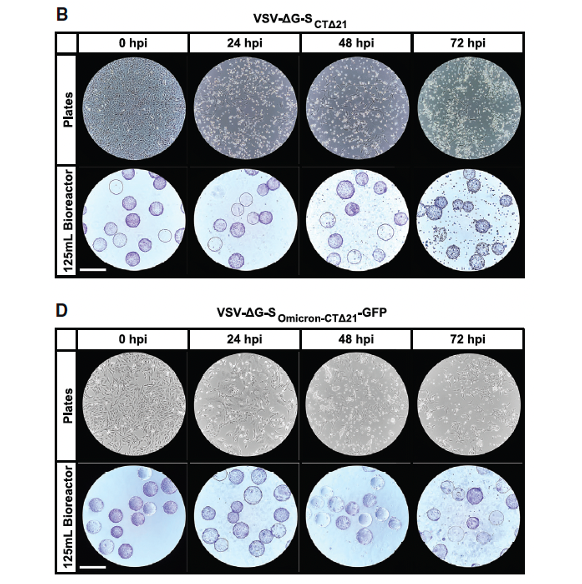

One of the key advancements highlighted in this study is the use of microcarriers in stirred-tank bioreactors to grow Vero cells, which are widely used for producing viral-vectored vaccines. Microcarriers provide a larger surface area for cell attachment and growth, making them ideal for scalable production in a bioreactor setting. This method significantly reduces the labor and space required compared to traditional plate-based systems, making it a highly efficient and economical solution for vaccine production.

The study achieved remarkable results with this approach. Vero cells grew to a density of 3.95 ± 0.42 × 10^6 cells/mL in 1-L stirred-tank bioreactors. Ancestral strain S-VSV reached a peak titer of 2.05 ± 0.58 × 10^8 plaque-forming units (PFUs)/mL at 3 days post-infection. When compared to growth in plate-based cultures, this was a 29-fold increase in virus production, meaning a 1-L bioreactor produces the same amount of virus as 1,284 plates of 15 cm. In addition, the omicron BA.1 S-VSV reached a peak titer of 5.58 ± 0.35 × 10^6 PFU/mL.

These results underscore the efficiency and scalability of using microcarriers for vaccine production. Not only does this method allow for high-density cell growth, but it also achieves substantial virus yields, crucial for producing vaccines at scale during pandemics.

Conclusion

Microcarrier-based cell culture in stirred-tank bioreactors represents a breakthrough in scalable and cost-effective SARS-CoV-2 vaccine manufacturing. This innovative approach enables the production of up to 200,000 vaccine doses from a single 1-liter bioreactor culture, drastically reducing the costs and resources associated with traditional methods. With the ability to produce high virus titers at lower costs, this method is poised to play a critical role in the preclinical and clinical development of vaccines for future pandemics.

By adopting this scalable technology, the global health community can enhance its preparedness for future pandemics, ensuring vaccines are produced quickly, efficiently, and at the scale required to meet global demand.

Get in touch with our team of experts for assistance with your vaccine production using Microcarriers.

To read the original article, click here.

Leave A Comment