The Growing Role of Microcarriers in Cell Culture

In regenerative medicine, cell therapy, and cultivated meat production, mesenchymal stem cells (MSCs) are vital for creating tissues like bone, cartilage, and muscle. However, producing these cells at a large scale is challenging because MSCs must attach to a surface to grow.

To overcome this limitation, researchers use microcarriers, small, bead-like scaffolds that float in bioreactors and provide a vast surface area for cell attachment. But not all microcarriers perform equally. Their surface chemistry plays a critical role in how well cells adhere, proliferate, and remain viable.

A recent study published in Biomolecules (2025) explored how collagen coatings can make microcarriers more effective for MSC expansion.

Study Spotlight: Evaluating Biocompatible Microcarriers for Better Cell Growth

Paper title: Evaluation of Biocompatible Materials for Enhanced Mesenchymal Stem Cell Expansion: Collagen-Coated Alginate Microcarriers and PLGA Nanofibers

Authors: Jaime-Rodríguez et al., Tecnológico de Monterrey, Mexico

DOI: 10.3390/biom15030345

Main Goal of the Study

The researchers aimed to develop and evaluate new biocompatible materials, specifically collagen-coated alginate microcarriers and PLGA (polylactic-co-glycolic acid) nanofibers, as improved growth surfaces for mesenchymal stem cell (MSC) proliferation.

They wanted to determine whether collagen coatings could enhance:

- Cell adhesion and growth,

- Material stability and compatibility, and

Scalability for therapeutic and biotechnological applications.

How the Experiment Was Conducted

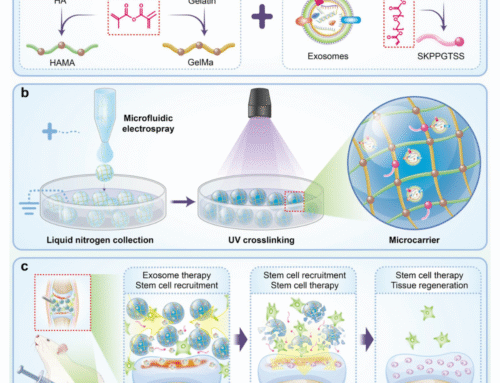

- Material Preparation:

- Alginate microcarriers were created using electrospraying, while PLGA nanofibers were made by electrospinning.

Both were coated with collagen to enhance cell attachment and mimic the natural extracellular environment.

- Alginate microcarriers were created using electrospraying, while PLGA nanofibers were made by electrospinning.

- Cell Culture:

- MSCs were isolated from Yorkshire pig bone marrow and grown in serum-free, antibiotic-free medium (NutriStem XF), an ethical and reproducible alternative to fetal bovine serum.

- Testing:

- Microscopy and SEM verified MSC attachment and morphology.

- Thermogravimetric (TGA) and FT-IR analyses confirmed collagen integration and increased material stability.

- ISO-10993 biocompatibility tests (EpiDerm™ and EpiOcular™) ensured the materials caused no irritation.

In addition to the alginate microcarriers, the researchers also tested collagen-coated PLGA nanofibers as a potential growth surface. These nanofibers supported MSC proliferation comparable to traditional flat culture plates. However, the collagen-coated alginate microcarriers showed superior scalability and overall cell growth, making them the standout performer in this study.

Key Findings: Collagen Makes a Difference

- Enhanced Cell Growth

- Collagen-coated alginate microcarriers produced the highest MSC proliferation, reaching 1.36 million cells after 96 hours, versus 1.02 million on a commercial control and 58,000 on uncoated alginate.

- In the study, both the experimental and commercial microcarriers were collagen-coated. The researchers observed that the alginate-based system supported higher mesenchymal stem cell proliferation under their specific test conditions.”

- Stronger Adhesion and Porous Growth

- SEM images showed MSCs tightly attached and even growing within the porous structure of alginate microcarriers, increasing total surface area for growth.

- Improved Material Stability

- Collagen raised alginate microcarriers’ thermal stability from 365 °C to 498 °C.

- FT-IR confirmed new hydrogen bonds between alginate and collagen, evidence of strong integration.

- Excellent Biocompatibility

- Both alginate and PLGA systems caused no skin or ocular irritation in ISO-10993 tests.

- Histological analysis showed intact tissue layers, confirming their biocompatibility.

Why This Matters for Microcarrier Research

This research shows how surface coatings can significantly improve microcarrier performance.

By combining biodegradable materials like alginate and PLGA with biomimetic coatings such as collagen, scientists can create materials that:

- Support faster and denser stem cell growth,

- Are biocompatible and safer for downstream use, and

Can be scaled for regenerative medicine, cell therapy, and cultivated meat applications.

Looking Ahead

Future work will focus on scaling collagen-coated systems in bioreactors, optimizing coating thickness and material composition, and applying them to various cell types.

This type of biomaterial research is paving the way toward more efficient, ethical, and sustainable large-scale cell manufacturing.

Conclusion

A recent study by Jaime-Rodríguez et al. (2025) explored how collagen coatings can make microcarriers more effective for MSC expansion.

It’s an exciting example of how surface engineering continues to advance scalable stem cell production for both medical and biotechnological innovation.

Jaime-Rodríguez, J., Vázquez-Vázquez, M., Espinosa-Hernández, V. M., Cervantes-Ugalde, D., Segura-Campos, M. R., & García-García, A. (2025). Evaluation of biocompatible materials for enhanced mesenchymal stem cell expansion: Collagen-coated alginate microcarriers and PLGA nanofibers. Biomolecules, 15(3), 345. https://doi.org/10.3390/biom15030345

Disclaimer:

This article summarizes findings from Jaime-Rodríguez et al., Biomolecules (2025).

The authors of that study did not use or evaluate Smart MCs’ products.

Our goal in sharing this publication is to highlight the use case and scientific potential of microcarriers in general, as part of ongoing developments in the field.

At Smart MCs, we follow new advances in microcarrier science closely, staying informed on research that shapes the future of scalable, high-quality cell culture.

If you’re exploring customisable microcarriers for your own cell culture applications, our team can help design solutions tailored to your needs.

Contact us at info@smartmcs.com.au or visit our page to request a quote.

Leave A Comment