Adherent cell culture is essential for many biotechnological applications, including stem cell expansion, vaccine production, and therapeutic manufacturing. A recent study by Seohyun Park, Hyunwoo Kim, and Duk Jae Oh, published in Biotechnology and Bioprocess Engineering (2024), introduces a funnel-type fluidized bed reactor that improves the efficiency and stability of microcarrier-based cell culture systems.

Challenges with Traditional Bioreactors

Microcarriers provide a high surface area for growing adherent cells, making them a key tool for large-scale production. However, traditional cylindrical bioreactors face significant challenges:

- Shear Stress: Mechanical stirring used to suspend microcarriers can damage sensitive cells like human mesenchymal stem cells (hMSCs).

- Sedimentation and Clogging: As cells grow, microcarriers become heavier and tend to settle or clog filters, disrupting culture performance.

- Operational Instability: Maintaining an optimal flow rate for fluidizing microcarriers is difficult in cylindrical designs, reducing efficiency.

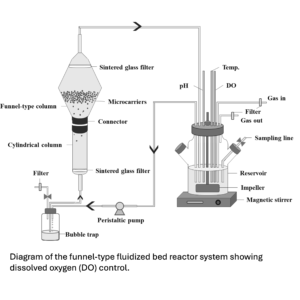

The Funnel-Type Fluidized Bed Reactor

The design overcomes these limitations by creating a stable and low-shear culture environment for microcarrier-based cell expansion. Here’s how it works:

- Funnel Design for Stable Fluidization:

- The tapered column allows the fluid velocity to gradually decrease as it rises, keeping microcarriers evenly suspended.

- Heavier microcarriers that would normally settle are naturally re-suspended at the narrower base of the funnel.

- Low-Shear Environment:

- Unlike traditional systems that rely on mechanical agitation, the funnel-type fluidized bed reactor uses gentle liquid flow, which minimizes shear stress and protects cell viability.

- Consistent Culture Stability:

- The reactor maintains stable microcarrier suspension throughout the culture process, ensuring uniform cell growth.

Study Results: Microcarrier-Based Cell Culture

The study tested the funnel-type fluidized bed reactor with two cell types—mouse fibroblasts (L929) and human mesenchymal stem cells (hMSCs)—on microcarriers.

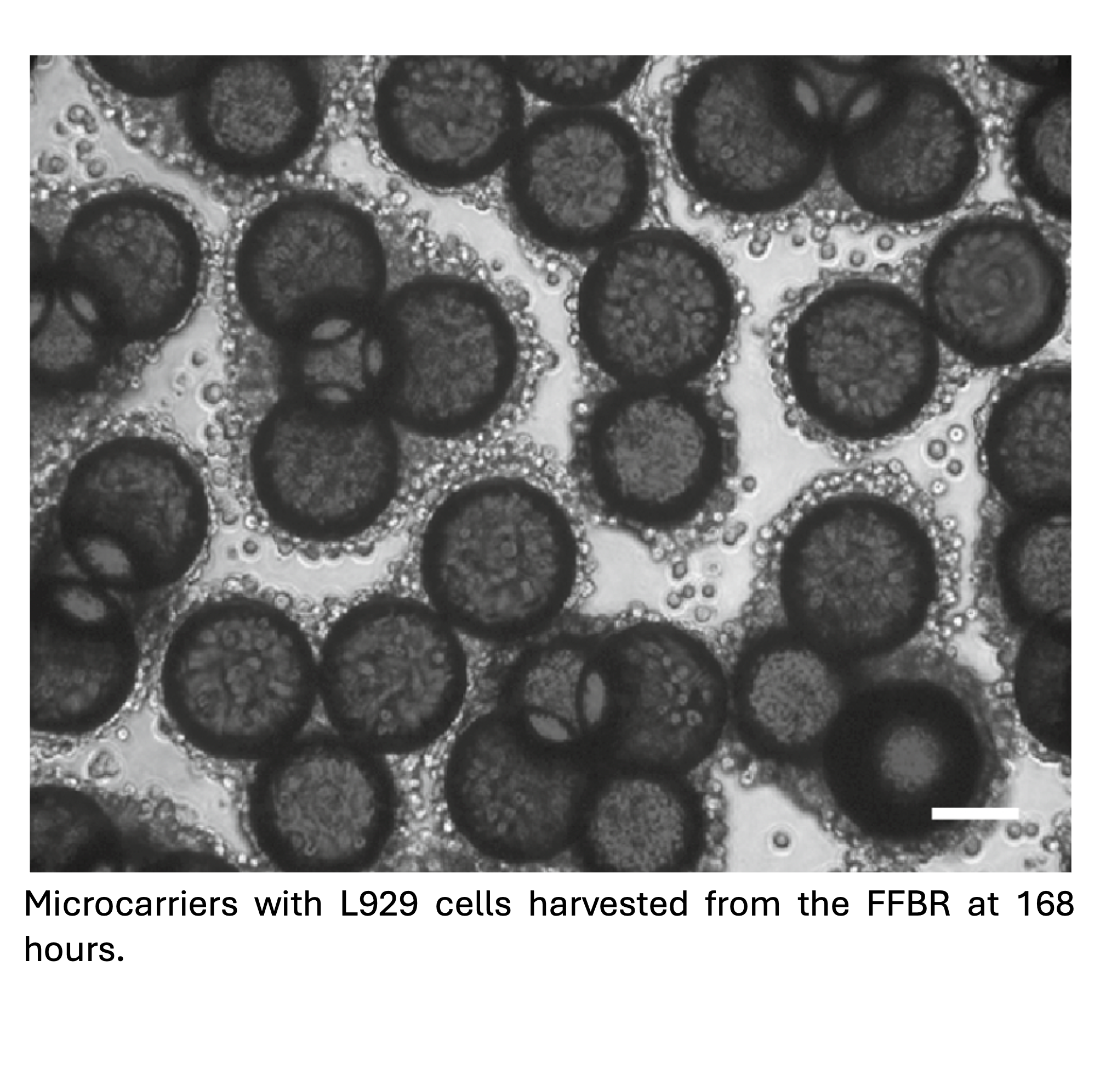

- L929 Cells:

- Stable fluidization was maintained, even as cells grew and added weight to the microcarriers.

- The funnel-type fluidized bed reactor achieved up to 1.45 times higher cell densities compared to standard 2D cultures.

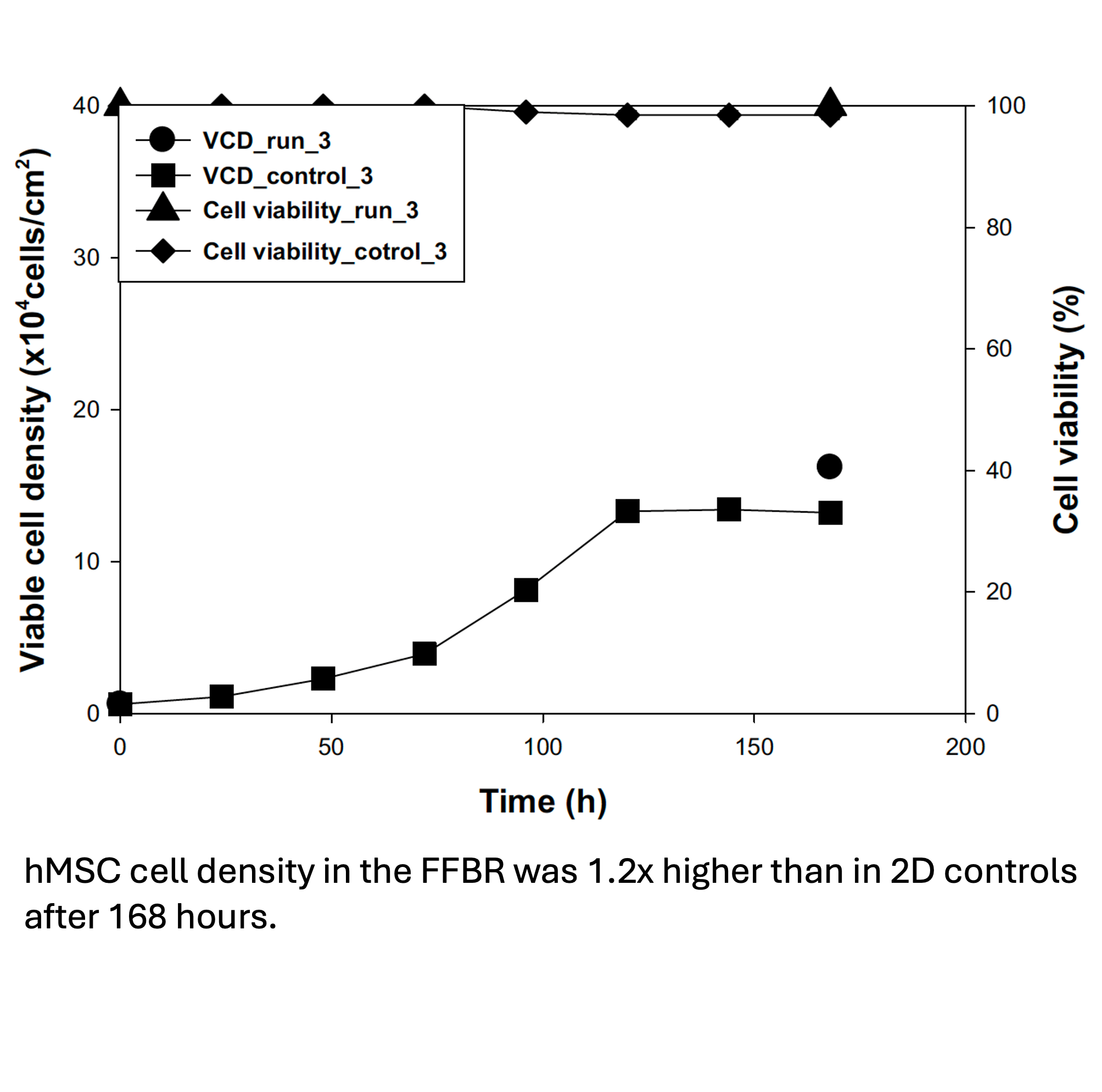

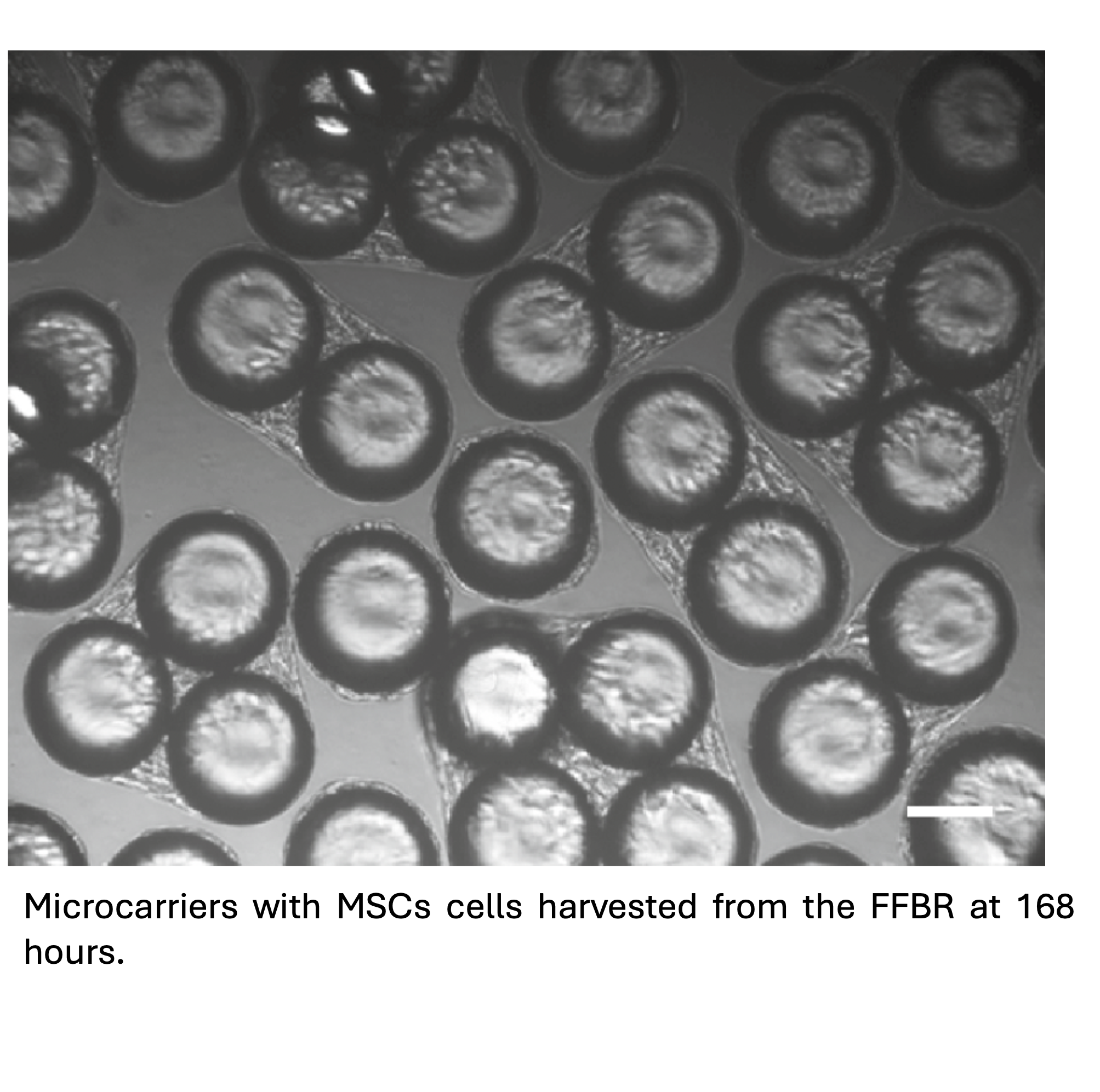

- hMSCs:

- hMSCs attached firmly to microcarriers and exhibited strong monolayer growth.

- Final cell densities were 1.2 times higher than in conventional 2D systems.

- Nutrient Stability:

Glucose and lactate levels were consistent throughout the culture, reflecting efficient cell growth and nutrient utilization.

Why This Matters

The funnel-type fluidized bed reactor offers a practical solution for large-scale adherent cell culture. By maintaining stable microcarrier suspension and minimizing shear stress, the funnel-type fluidized bed reactor is particularly useful for:

- Stem cell expansion

- Vaccine production

- Cell therapy manufacturing

- Tissue engineering

The reactor’s design ensures reliable performance, making it suitable for research, development, and commercial applications.

Conclusion

This study demonstrates that the funnel-type fluidized bed reactor is an effective system for microcarrier-based adherent cell culture. Its ability to provide a stable, low-shear environment addresses key challenges in large-scale cell production.

Learn More

Interested in improving your cell culture efficiency? Contact us today to learn more about our microcarrier solutions and how they can support your work.

At Smart MCs, we offer high-quality microcarriers that can support this type of advanced bioreactor system. Designed for scalability and performance, our microcarriers are ideal for a range of applications, including stem cell culture, vaccine production, and therapeutic manufacturing.

To read the full article, click here.

Leave A Comment