Smart MCs Pty Ltd is proud to announce its participation in a $900,000 research collaboration with the University of New South Wales (UNSW), supported by $900,000 in funding through the Australian Research Council (ARC) Linkage Program. This project is led by A/Prof. Christopher Marquis and Prof. Kris Kilian at UNSW. The project will focus on expanding Smart MCs’ customisable microcarrier technology to support large-scale biomanufacturing, including the production of vaccines, viral vectors, and cell-based therapies.

Enabling Scalable Cell Manufacturing Across Industries

Biomanufacturing plays a vital role in producing life-saving biologics such as vaccines, advanced therapies, and gene therapies. These products are essential for treating a wide range of health conditions, including infectious diseases, cancer, rare genetic disorders, and autoimmune diseases. Biomanufacturing also underpins the large-scale production of viral vectors used in gene therapies, as well as the development of emerging cell-based treatments that rely on adherent cell culture systems. Ensuring scalable, reliable, and cost-efficient biomanufacturing processes is critical to meeting global demand for these therapies, improving patient access, and building resilient healthcare supply chains.

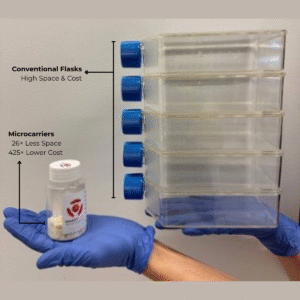

Traditionally, adherent cells have been grown in two-dimensional (2D) systems such as flasks, roller bottles, or multilayer culture plates. While these methods are widely used for research and small-scale production, they present clear limitations when scaling up for commercial manufacturing, including space inefficiencies, labour intensity, and inconsistent yields.

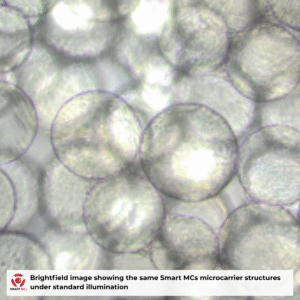

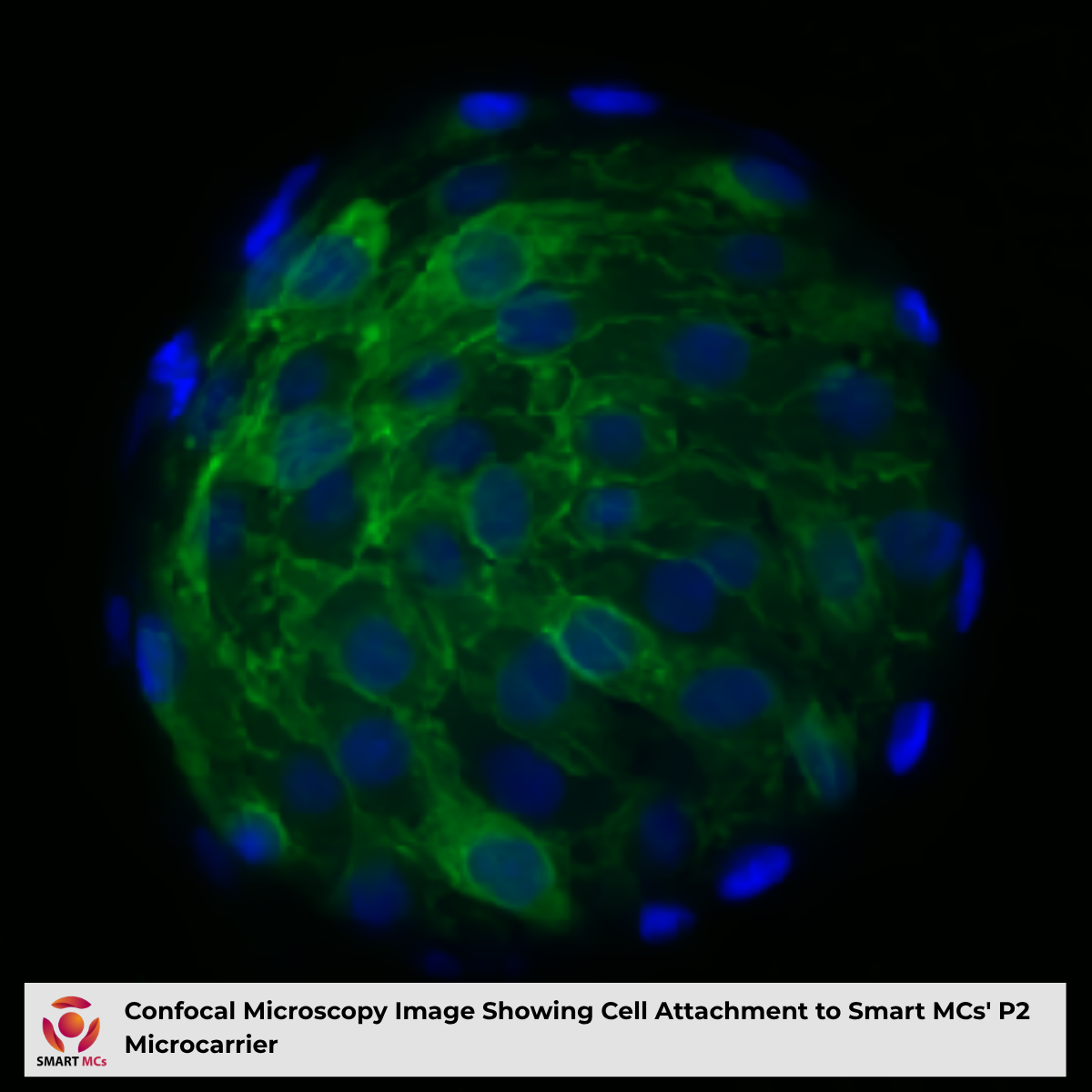

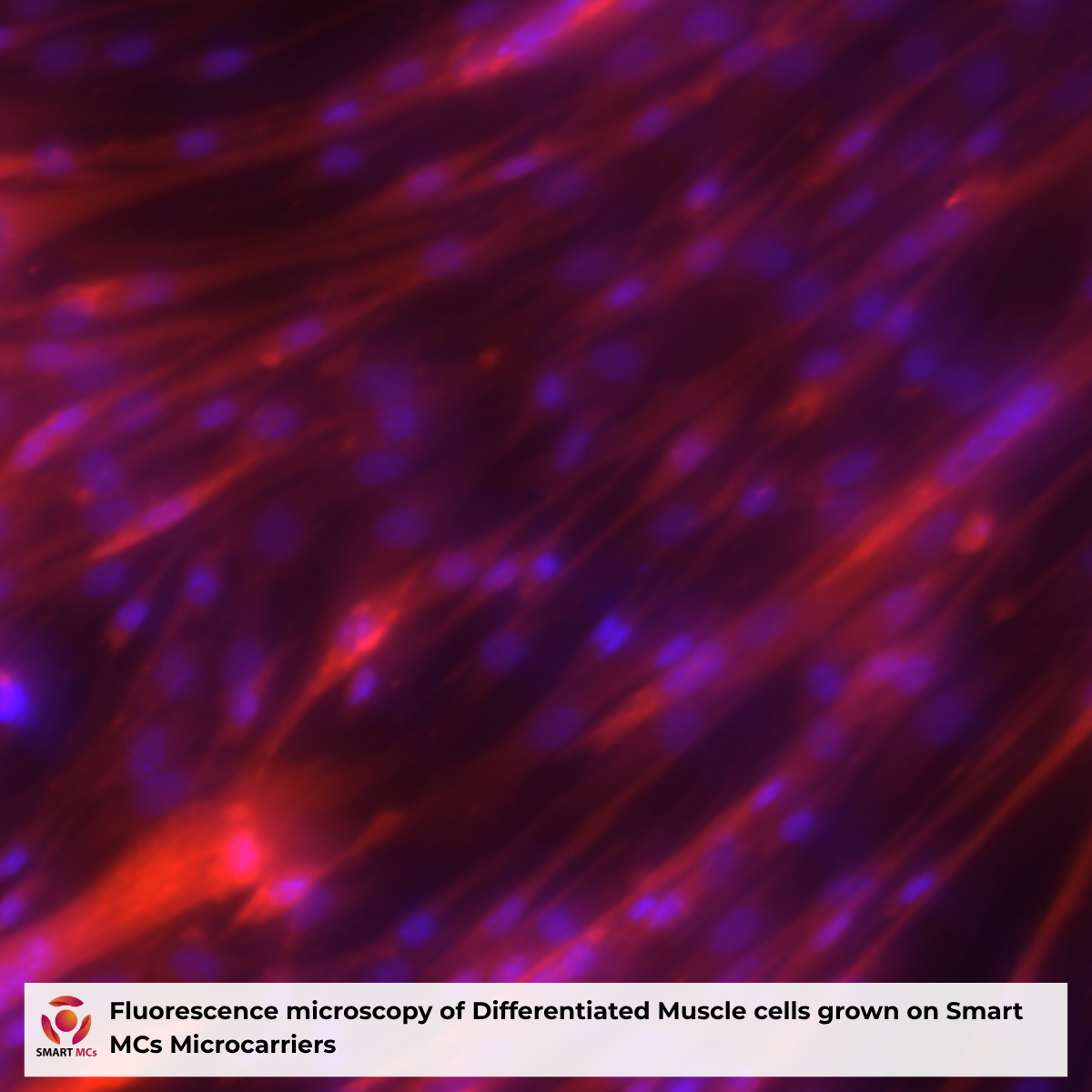

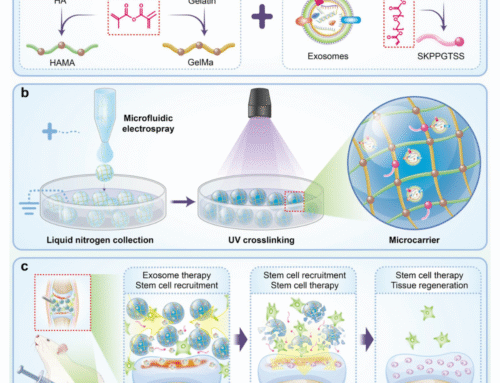

Microcarriers provide a three-dimensional (3D) solution by offering microscopic surfaces for cells to attach and grow within bioreactors. This approach enables higher-density cell cultures, significantly increases production volumes, and makes more efficient use of space, bioreactor capacity, and raw materials.

Smart MCs has already developed a versatile microcarrier platform designed to support scalable adherent cell culture. This ARC-funded project builds on that foundation, further enhancing the platform’s flexibility and performance for a wide range of cell manufacturing processes.

Customisable Microcarrier Technology for Diverse Applications

The Smart MCs microcarrier platform is designed to be highly adaptable, with the ability to modify key properties to meet specific process requirements:

- Surface Charge — Optimising how cells attach, spread, and proliferate on the carrier surface.

- Surface Coatings — Tailoring the microcarrier to support specific cell types, including stem cells, or production cells for viral vectors.

- Size Adjustment — Customising microcarrier dimensions to meet the requirements of different processes and cell types.

- Stiffness — Modifying microcarrier rigidity to influence cell behaviour and support optimal cell growth and differentiation.

This adaptability provides manufacturers with the flexibility to optimise processes, improve production yields, reduce costs, and support consistent, high-quality manufacturing at scale.

“Scalable, adaptable microcarriers are critical to advancing biomanufacturing and cell-based production,” said Dr Payar Radfar, CEO of Smart MCs. “This project allows us to extend the capabilities of our platform to meet the growing demands of industries like biologics, vaccine manufacturing, and cell therapy.”

A Collaborative Approach to Expanding Biomanufacturing Capabilities

The ARC Linkage Project brings together Associate Professor Christopher Marquis and Professor Kristopher Kilian from UNSW, along with the team from Smart MCs. The project aims to further broaden the application of Smart MCs’ microcarrier technology across critical industries, including:

Vaccine Manufacturing — Enhancing large-scale, consistent production of vaccines, including those using viral vectors.

Cell and Gene Therapy Manufacturing — Supporting scalable production of viral vectors essential for gene therapies and advanced medicines.

Stem Cell Manufacturing — Enabling the large-scale expansion of stem cells, including mesenchymal stem cells derived from sources such as Wharton’s Jelly and bone marrow.

Strengthening Australia’s Sovereign Manufacturing Capacity

The ARC Linkage Program fosters collaboration between research organisations and industry partners to develop practical, innovative solutions for national challenges. This project aligns with Australia’s broader commitment to building sovereign biomanufacturing capacity and supporting the development of sustainable technologies.

Smart MCs’ work on customisable microcarriers reflects the company’s mission to deliver innovative biomaterials that support scalable, efficient, and high-quality cell manufacturing across the life sciences and biopharmaceutical sectors.

Leave A Comment