In the cultured meat industry, scalability and optimised cell culture processes are crucial for commercial success. Microcarriers (MCs) offer a reliable solution for achieving high cell densities, making them essential in producing large volumes of cells needed for cultivated meat. However, customization of microcarriers is key to maximising their effectiveness, particularly when working in serum-free environments.

A recent study by Bodiou et al., published in Frontiers in Bioengineering and Biotechnology (2024), highlights the importance of customised microcarrier coatings in improving cell attachment, proliferation, and purity. The research underscores how attachment-promoting compounds (APCs) such as vitronectin and laminin can significantly enhance cell growth in serum-free media, enabling a scalable and efficient production process. These findings reinforce the value of tailored microcarriers for driving cleaner, more sustainable, and ethical solutions in the cultured meat industry.

What Are Microcarriers and Why Are They Critical for Cultivated Meat?

Microcarriers are tiny particles that provide a surface for cells to attach and grow in suspension cultures, particularly in stirred-tank bioreactors. Their large surface-to-volume ratio is ideal for achieving the high cell densities needed in cultured meat production, particularly with adherent cell types like muscle satellite cells. The ability to control bioreactor conditions, such as temperature, pH, and oxygen levels, allows for optimised cell proliferation and quality control. For cultured meat applications, the use of MCs in serum-free environments supports ethical and sustainable practices, which are important considerations for the industry and consumers alike.

Customising Microcarriers for Enhanced Cell Growth and Purity

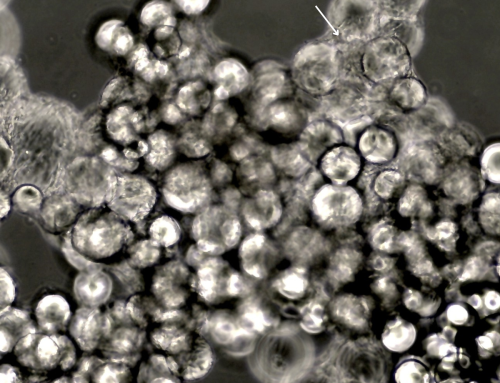

Day 1 images (×10, scale bar = 300 μm) of bSCs on microcarriers with vitronectin, laminin, fibronectin, or no coating in serum-free growth medium.

Bodiou and his team explored the effects of different commercial microcarriers (MCs) and serum-free media on bovine satellite cell (bSC) growth. They found that certain microcarriers with specific surface properties were more effective in promoting cell attachment and proliferation. The study highlighted the value of using attachment-promoting compounds (APCs), such as vitronectin and laminin, to further enhance the performance of microcarriers. These APCs significantly improved cell attachment and growth rates, especially when applied as MC coatings, allowing adherent cells to grow efficiently in serum-free media while maintaining high purity.

One of the most notable findings was that vitronectin could be used solely as a coating for MCs, rather than as a continuous supplement in the culture medium. This approach not only supported robust cell growth but also eliminated the need for additional costly supplements during medium exchanges, reducing production costs and simplifying the culture process. Laminin, another APC tested, also showed benefits for cell attachment and growth, although it was associated with slightly more variability in cell purity.

Benefits of Customisable Microcarriers in Cultured Meat Production

- Improved Cell Attachment and Proliferation: customised coatings, like vitronectin, significantly boost cell attachment and growth rates, helping achieve high cell densities faster. This efficiency is essential for large-scale cultured meat production.

- Cost Savings: Using APCs like vitronectin solely as a coating, rather than as a continuous supplement, reduces the need for expensive medium additives during each exchange, resulting in substantial cost savings while maintaining high cell growth and purity.

- Scalability for Commercial Production: Custom microcarriers are already suitable for bioreactors, and their efficiency improves when optimised for specific cell types and conditions. This adaptability makes it easier for companies to meet the growing demand for cultivated meat without compromising quality.

- Alignment with Sustainable and Ethical Goals: Customisable microcarriers support a serum-free culture, an animal-free approach that aligns with the industry’s sustainability goals. These tailored MCs promote a more ethical and environmentally conscious production process by eliminating serum and reducing media supplements.

Customization as the Future of Cultivated Meat Production

As the industry evolves, the ability to tailor microcarriers to specific cell types and culture environments will be crucial for scalable, efficient production. Custom microcarriers allow cellular agriculture companies to improve production efficiency, control costs, and meet ethical standards that align with consumer expectations.

Conclusion

Customisable microcarriers are driving significant advancements in cultured meat production. By enhancing cell attachment, reducing costs, and supporting sustainable practices, these tailored MCs are essential for the future of scalable, ethical cultured meat. With continued research and development, customisable microcarriers will play an increasingly important role, making cultivated meat a viable and desirable alternative to traditional meat.

Click here to read the full article.

Still exploring the world of microcarriers? Check out our resources for more detailed information.

Want to dive deeper into our microcarriers? Visit our product page for all the details, or drop us a message at info@smartmcs.com.au. We’d love to help you customise the perfect microcarriers for your specific needs!

Leave A Comment