A 2025 BMC Veterinary Research study shows how microcarriers in spinner flasks enable scalable MSC exosome production with ~81 nm size, stable charge, and high particle yield plus storage, bioactivity, and safety insights.

In a recent study…

Title: Scalable production of anti-inflammatory exosomes from three-dimensional cultures of canine adipose-derived mesenchymal stem cells: production, stability, bioactivity, and safety assessment (BMC Veterinary Research, 2025) by Anatcha Thongsit, Saranyou Oontawee, Parkpoom Siriarchavatana, Watchareewan Rodprasert, Poorichaya Somparn, Daneeya Na Nan, Thanaphum Osathanon, Hiroshi Egusa, and Chenphop Sawangmake.

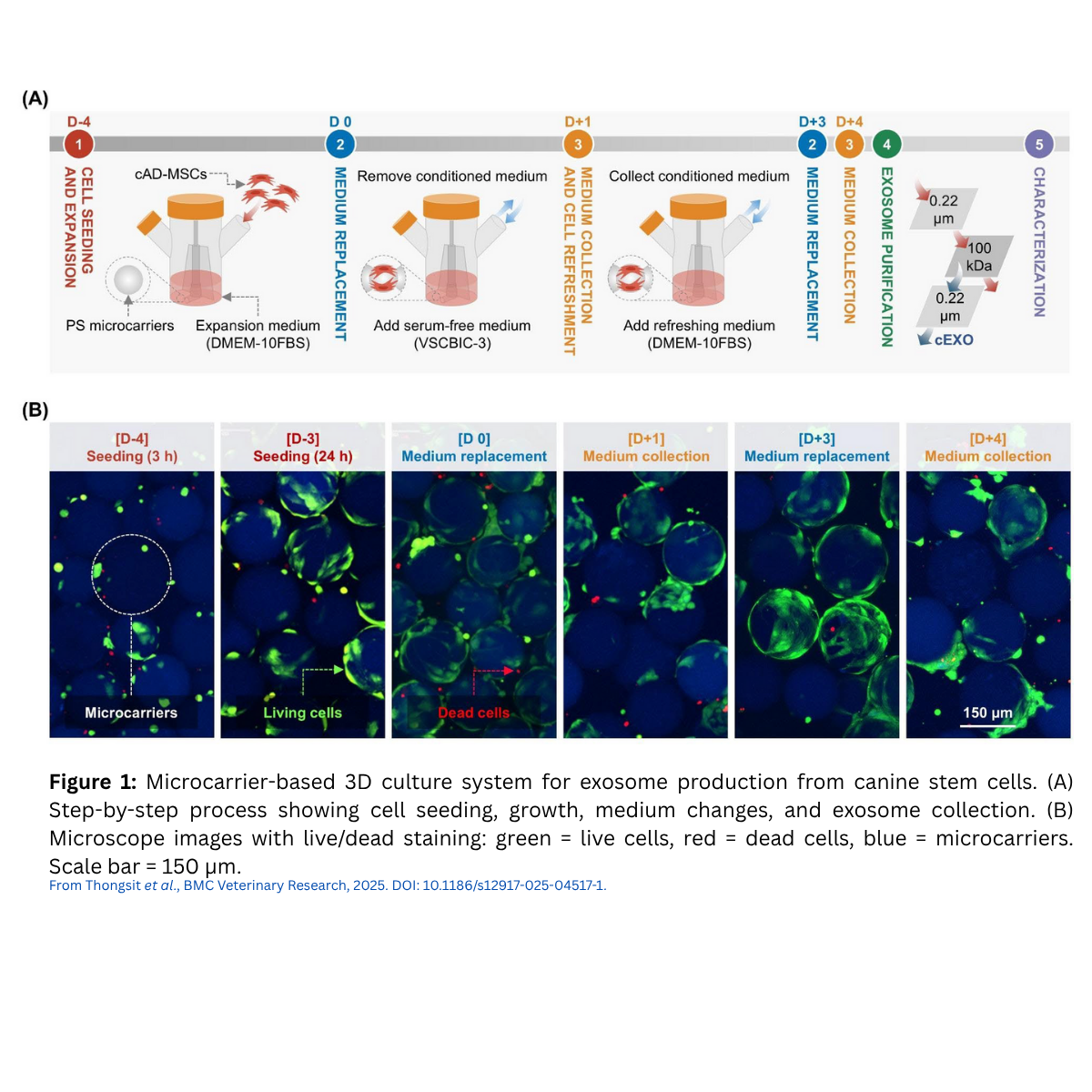

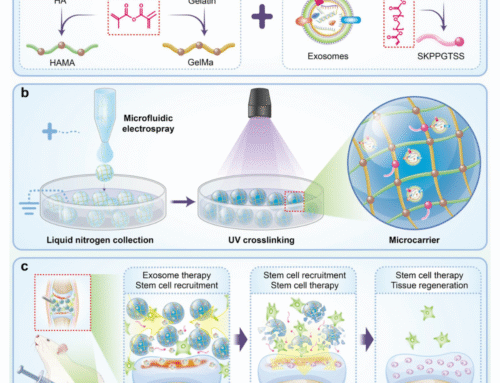

Why it matters: The team evaluated a microcarrier-based 3D culture (spinner flask with polystyrene microcarriers) to make mesenchymal stem cell exosomes (cEXO), which are exosomes derived from canine adipose-derived mesenchymal stem cells (cAD-MSCs). In short, cEXO = “canine MSC exosomes.” They then characterised yield/physicochemical properties, stability, bioactivity, and safety, the critical checkpoints for real-world microcarrier workflows..

Key findings

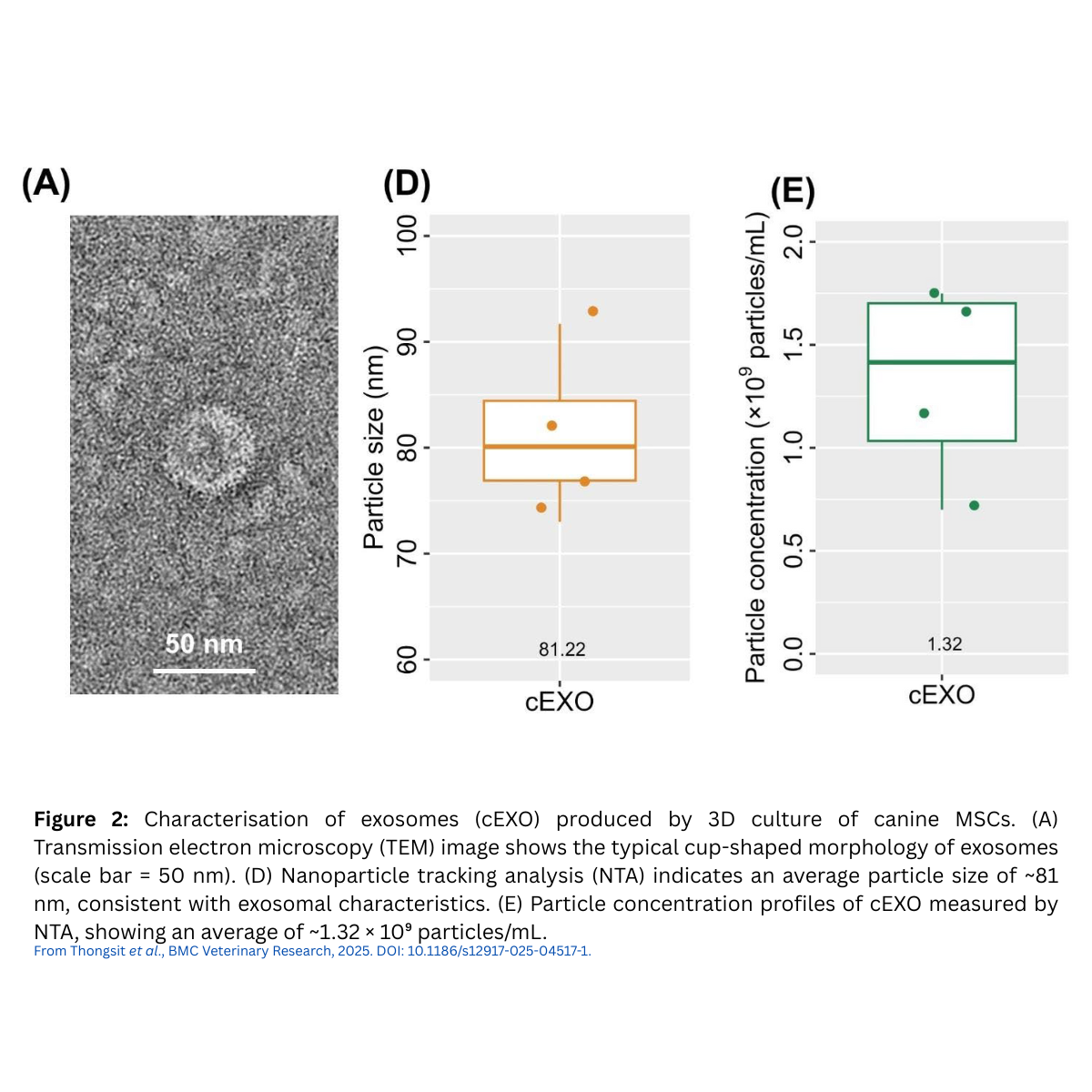

- Scalable production on microcarriers: The 3D microcarrier system produced exosomes with a mean size ~81 nm, negative surface charge, and high particle concentration of ~1.32 × 10⁹ particles/mL.

- Viability dynamics: Confocal imaging showed that cell viability dipped slightly during serum-free collection windows but recovered after medium refresh, a useful signal for scheduling collection cycles

- Stability: Exosomes remained more stable when stored at −20 °C; 4 °C led to a significant drop in particle counts by Day 30.

- Bioactivity: In LPS-stimulated macrophages, the exosome prep reduced nitric oxide production, showing a reverse dose-dependent anti-inflammatory effect — lower doses had stronger inhibition — with no cytotoxicity observed.

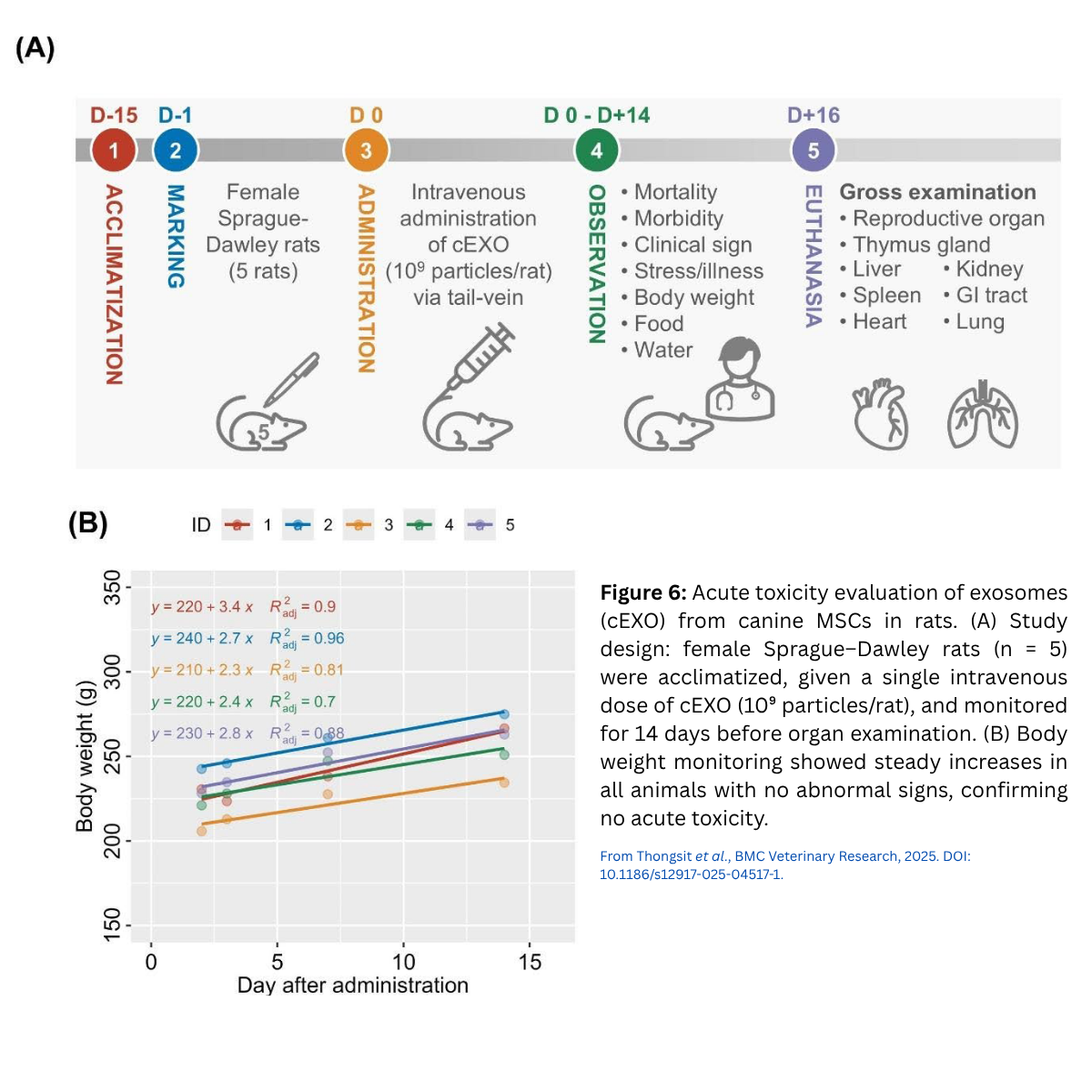

- Safety: The exosomes passed both in vitro and in vivo checks. Fibroblast viability remained unaffected in culture, and in a 14-day acute toxicity screen in rats (single IV dose, with monitoring of clinical signs, weight, blood work, and organ histology), no adverse effects were detected.

How many exosomes did they get?

After processing and buffer exchange, the final exosome solution volume was ~205 mL at ~1.32 × 10⁹ particles/mL, indicating a batch on the order of ~2.7 × 10¹¹ particles (concentration × volume; simple calculation for context).

At a glance: ~81 nm size · ~−19.5 mV zeta · ~1.32 × 10⁹ particles/mL → ~2.7 × 10¹¹ total particles in ~205 mL.

What the Conclusion says

- Feasible and scalable: The microcarrier-based 3D system supports repeatable production with credible physicochemical profiles.

- Functional activity: The prep showed anti-inflammatory activity in vitro (NO inhibition) while maintaining cell viability—evidence that it’s not “just particles.”

- Safer storage choice: Frozen (−20 °C) holds up better than 4 °C for particle counts over 30 days—useful when writing SOPs and planning logistics.

- Early safety signal: The acute toxicity screen in rodents was unremarkable (no mortality/abnormalities), supporting continued development.

Why microcarriers are a strong fit for exosome programs

- Scale & space efficiency: Microcarriers provide high surface area in stirred vessels—easier to scale than stacks of flasks.

- Process control: You can schedule serum-free collection windows and refresh steps to balance yield vs. cell health (the study observed dips/recovery exactly at these phases).

- QC ready: The study’s framework—NTA size/concentration, zeta, marker check, potency, stability—maps well to practical lab QC.

Practical tips (to translate this into your lab)

- Pilot your culture setup. Start with a spinner flask and microcarriers. Define your workflow as attachment → expansion → short serum-free collection → refresh. (The paper’s viability pattern shows why refresh matters.)

- Decide on your storage strategy early. If you must hold material at 4 °C, validate it against frozen conditions, since particle counts fell significantly at 4 °C by Day 30.

- Plan your QC checklist. At minimum, track particle size (~80 nm), zeta potential (~−20 mV), counts (via NTA), a potency readout (e.g., macrophage nitric oxide inhibition), and storage stability under your logistics conditions.

Where Smart MCs fits in

We design microcarriers to support strong attachment, healthy growth, and predictable harvests in stirred systems. Tell us your cell type, vessel, and target yield, we’ll recommend surface chemistry & size and share a starter seeding/stirring playbook aligned to your setup.

Get a quote · Request a consult

Disclosure :

Leave A Comment