Microcarriers are tiny spherical materials used to grow cells in 3D, especially when large numbers of cells are needed. A recent study explored how a commonly used commercial microcarrier compared with newly developed GelMA-based microcarriers that contain interconnected pores. This comparison helps illustrate how microcarrier design can influence cell behaviour.

A recent study titled “Dual Ice Crystal Growth Strategy-Enabled Fabrication of Interconnected-Porous GelMA Microcarriers for Stemness Enhancement and Cellular Characteristic Preservation” by Huili Kang, Dong Zhang, Houming Zhou, Zhenhua Huang, Yina Xie, Fangping Chen, and Changsheng Liu, published in Biomaterials Advances in 2025, examined how different microcarrier structures influence cell attachment, proliferation, and phenotype in 3D culture.

The study highlights how pore architecture and material design can shape the behaviour of stem cells, endothelial cells, and epithelial cells in suspension and bioreactor-based systems.

Why This Study Matters

As 3D cell culture and bioprocessing continue to grow, understanding how cells respond to different microcarrier structures is increasingly important. Features such as pore size, interconnected pathways, stiffness, and material chemistry can influence:

- Nutrient and oxygen diffusion

- Cell attachment efficiency

- Spreading and migration

- Maintenance of natural cell characteristics

- Long-term culture stability

This study provides a useful example of how microcarrier engineering can be aligned with specific cell types and applications.

Microcarriers Examined in the Study

Standard Commercial Microcarrier

Used as the benchmark control:

- Smooth surface

- No interconnected internal pores

- Commonly used for general cell expansion in 3D systems

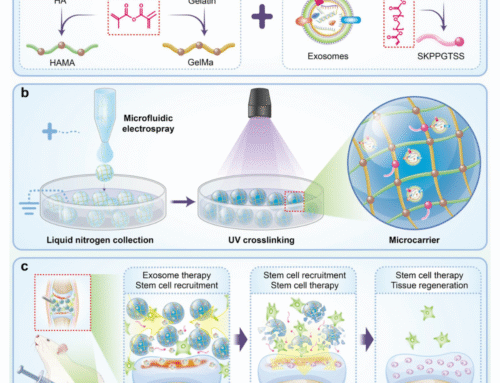

GelMA-Based Porous Microcarriers

Created using a dual ice-crystal method that generates:

- Highly interconnected pores (12–42 µm)

- Tunable structural properties based on freezing temperature

- A more biomimetic environment that allows cells to interact in 3D

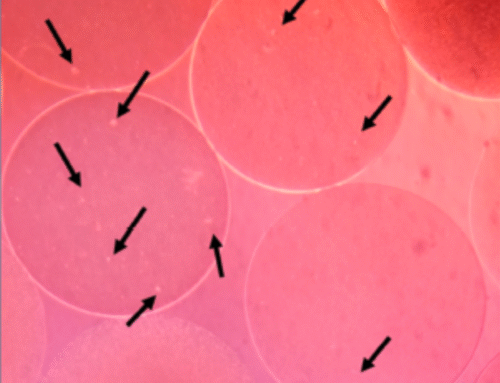

These GelMA microcarriers were produced in three variants, PMS20, PMS60, and PMS196, each created by freezing at different temperatures. The freezing temperature determines how large the ice crystals grow inside the microcarrier, which ultimately sets the pore size and internal connectivity.

- PMS20 (–20 °C): large pores

- PMS60 (–60 °C): medium pores

- PMS196 (–196 °C): smallest, highly interconnected pores

These differences matter because each pore structure creates a distinct 3D microenvironment, and different cell types respond better to different architectures.

Quick Comparison of the Variants

| Variant | Freezing Temp | Avg. Pore Size | Best For | Key Notes |

| PMS20 | –20 °C | 41.79 ± 7.40 μm | General culture | Largest pores; lowest attachment for some cell types |

| PMS60 | –60 °C | 24.26 ± 3.34 μm | Stem cells (BMSCs) | Best stemness maintenance and attachment |

| PMS196 | –196 °C | 11.53 ± 2.00 μm | Endothelial cells (HUVECs) & Epithelial cells (mRTECs) | Smallest pores; strongest proliferation and phenotype stability |

Key Observations From the Study

1. Bone Marrow Mesenchymal Stem Cells (BMSCs)

The medium-pore GelMA microcarrier (PMS60) supported:

- Strong cell attachment (around 91%)

- High expression of stemness markers

- Upregulation of Nanog and Sox2

- Maintenance of tri-lineage differentiation ability

2. Endothelial Cells (HUVECs)

The smallest-pore variant (PMS196):

- Supported high attachment and viability

- Promoted formation of interconnected, capillary-like networks

- Increased expression of angiogenesis-related genes such as VEGF, CD31, and HIF-1α

3. Renal Tubular Epithelial Cells (mRTECs)

PMS196 also showed:

- Stable expression of epithelial markers such as CK18

- Reduced expression of EMT-related markers

- Better maintenance of epithelial identity over time

Summary of Findings

- Microcarrier structure, especially pore size and connectivity, influences cell attachment, proliferation, and phenotype in 3D culture.

- Different pore architectures supported different cell types, suggesting that microcarrier design may need to be tailored to specific applications.

- These observations contribute to ongoing research into advanced microcarriers and scalable 3D cell manufacturing.

Kang, H., Zhang, D., Zhou, H., Huang, Z., Xie, Y., Chen, F., & Liu, C. (2025). Dual ice crystal growth strategy-enabled fabrication of interconnected-porous GelMA microcarriers for Stemness enhancement and cellular characteristic preservation. Biomaterials Advances, 177, 214410. https://doi.org/10.1016/j.bioadv.2025.214410

Want customisable microcarriers or GelMA hydrogel?

Contact us at info@smartmcs.com.au for more details!

Leave A Comment