A newly published study in Biomedical Materials validates Smart MCs’ X1 microcarriers, a fully customisable and dissolvable platform for large-scale adherent cell culture. The gelatin-based carriers were shown to outperform a widely used commercial benchmark across multiple sectors, including cultivated meat, regenerative medicine, and vaccine production. This article breaks down what X1 microcarriers are, why their design matters, and the key findings from the study.

Smart MCs Pty Ltd is proud to announce the publication of a major study in the journal Biomedical Materials, validating the performance of our proprietary X1 Microcarriers, a customisable, dissolvable microcarriers designed for large-scale adherent cell culture.

The study, titled “Maximising adherent cell production via customisable and dissolvable bio-polymer microcarriers,” demonstrates how tuning physical characteristics of X1 microcarriers such as stiffness, surface charge, and particle size can significantly improve cell proliferation, harvesting efficiency, and biological outcomes across a range of applications including cultivated meat, stem cell therapies, and vaccine manufacturing.

What Are Microcarriers, and Why Do They Matter?

Microcarriers are tiny beads that provide surface area for cells to grow in suspension. They are essential for cultivating adherent cells, those that must attach to a surface to proliferate, within stirred bioreactors. Compared to traditional 2D culture in petri dishes or flasks, microcarrier-based culture allows for much greater cell yields in a smaller volume, making them crucial for:

- Cultured meat production

- Stem cell therapy manufacturing

- Viral vaccine and gene therapy production

By increasing the available surface area inside a bioreactor, microcarriers enable industrial-scale cell growth. But while the concept is powerful, the choice of material and design greatly impacts performance.

Why Traditional Microcarriers Fall Short

Most commercial microcarriers are made from materials like polystyrene (plastic) or dextran (a synthetic sugar polymer). These materials are inert, stable, and compatible with basic cell growth, but they introduce several practical limitations:

- Non-dissolvable:

Cells must be separated from the carrier through mechanical filtration or centrifugation, which increases the risk of cell loss, damage, and contamination. - Not biodegradable or edible:

In applications like cultivated meat, these materials can’t remain in the final product. Removing them adds time, cost, and regulatory complexity. - Fixed properties:

Commercial microcarriers typically have one size, one stiffness, and one surface chemistry, regardless of the cell type. This limits their adaptability to different bioprocesses.

These drawbacks can reduce cell yield, complicate downstream processing, and hinder scale-up.

Smart MCs’ Solution: The X1 Microcarrier Platform

To address these issues, Smart MCs developed X1 microcarriers fully customisable, and dissolvable alternative.

Key Features of X1 Microcarriers:

| Feature | What It Does |

| Biodegradable & edible | Suitable for food-grade and therapeutic use |

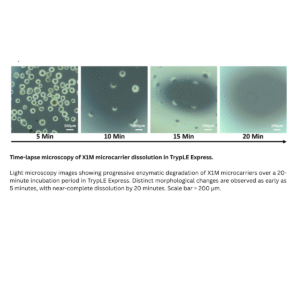

| Enzymatically dissolvable | Breaks down in <30 minutes using standard enzymes (e.g. TrypLE) |

| Tunable stiffness | Adjusted to match natural tissue environments for different cell types |

| Custom surface charge | Enhances cell attachment, spreading, or differentiation |

| Controlled size distribution | Minimises clumping and improves mixing efficiency in bioreactors |

By enabling researchers and manufacturers to tailor the microenvironment, the X1 platform leads to more efficient growth, simplified harvesting, and better downstream compatibility.

Results from the Study

The peer-reviewed study tested X1 microcarriers across five cell lines representing three major industrial applications: cultivated meat, stem cell therapy, and vaccine/viral vector production. A widely used commercial microcarrier was included for comparison under matched conditions.

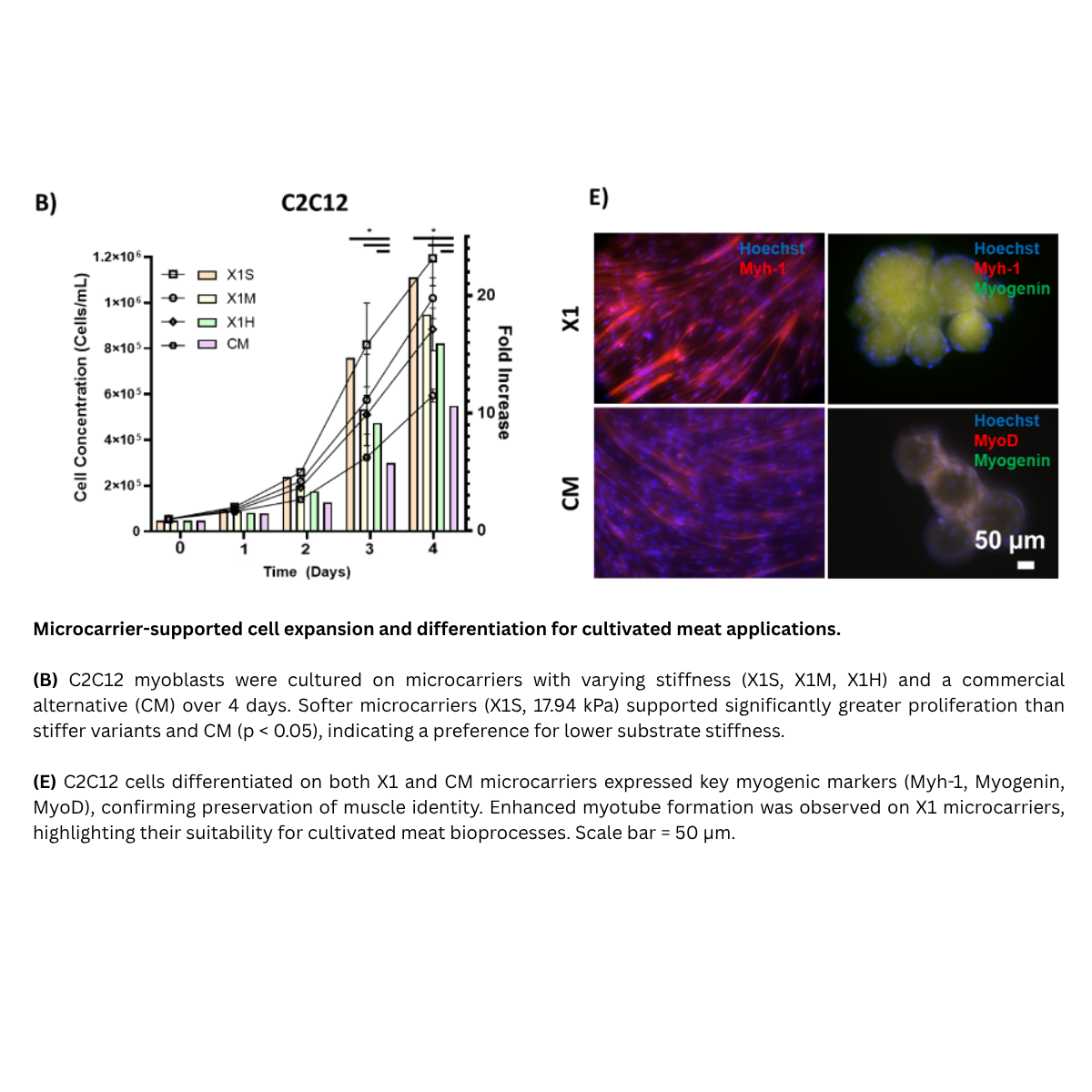

Cultivated Meat

Cell types:

- C2C12 (mouse muscle precursor)

- L929 (fibroblast)

Key findings:

- Up to 2× higher cell proliferation on X1 MCs compared to the commercial benchmark

- Myoblasts cultured on X1 showed significantly higher expression of MyoG and Myf4, key genes involved in muscle differentiation

- Softer microcarriers (~18 kPa stiffness) enhanced myoblast expansion, simulating damaged muscle tissue mechanics

- Cells formed bridges across MCs, indicating strong surface interaction and fusion potential

Implication: Higher growth and better muscle cell formation means X1 is highly suited for scalable cultured meat production.

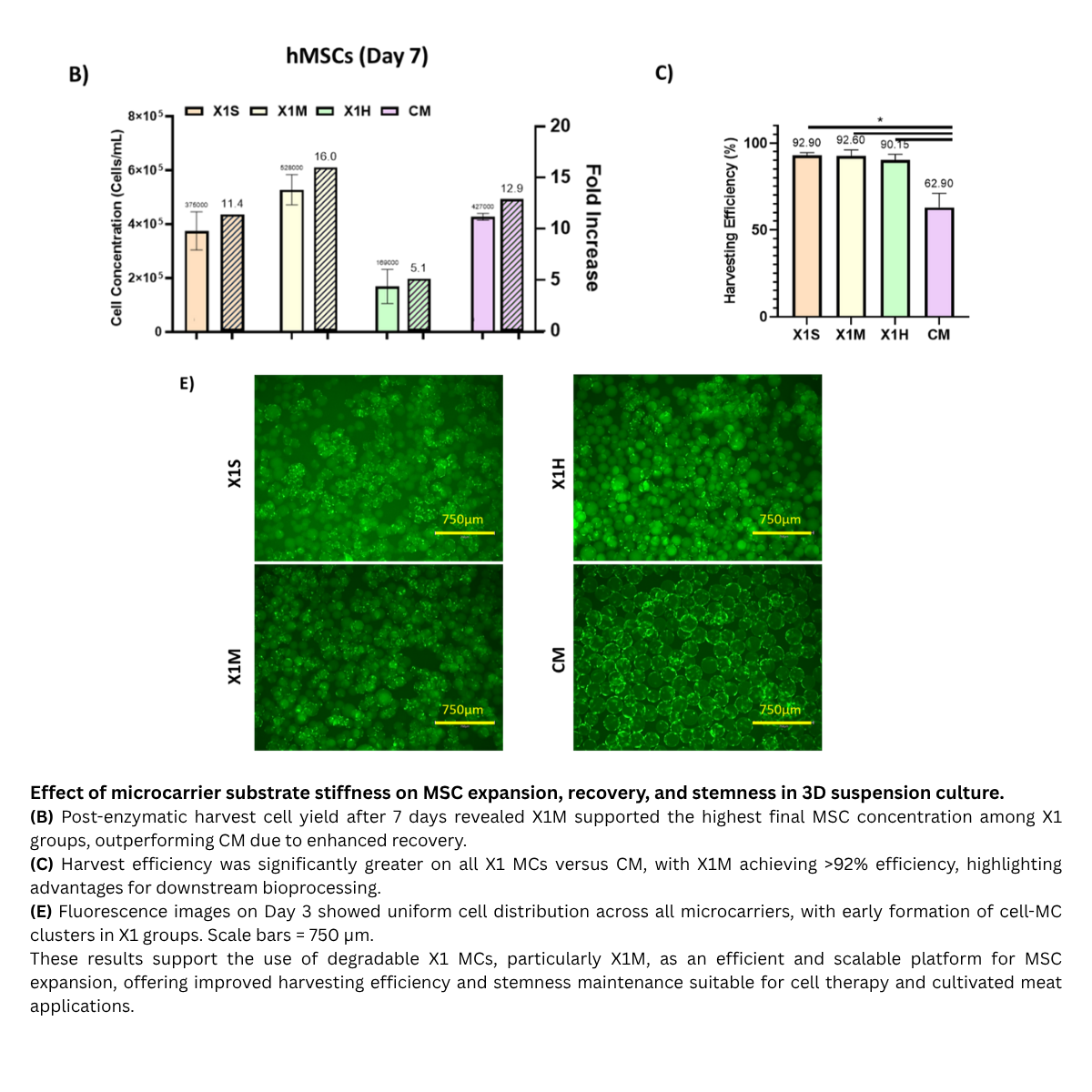

Regenerative Medicine

Cell type:

- Human Wharton’s Jelly-derived Mesenchymal Stem Cells (MSCs)

Key findings:

- 93% post-harvest recovery with X1 MCs vs. ~63% with the benchmark commercial microcarrier, due to full enzymatic dissolution

- MSCs retained key identity markers (CD73, CD90, CD105) across all groups

- CD105 expression was higher on X1 MCs — suggesting improved stem cell maintenance

- Despite slightly lower growth before harvesting, the net cell yield was higher thanks to the efficient dissolution process

Implication: X1 MCs provide a gentler, more efficient platform for MSC expansion and harvest—ideal for clinical and research use.

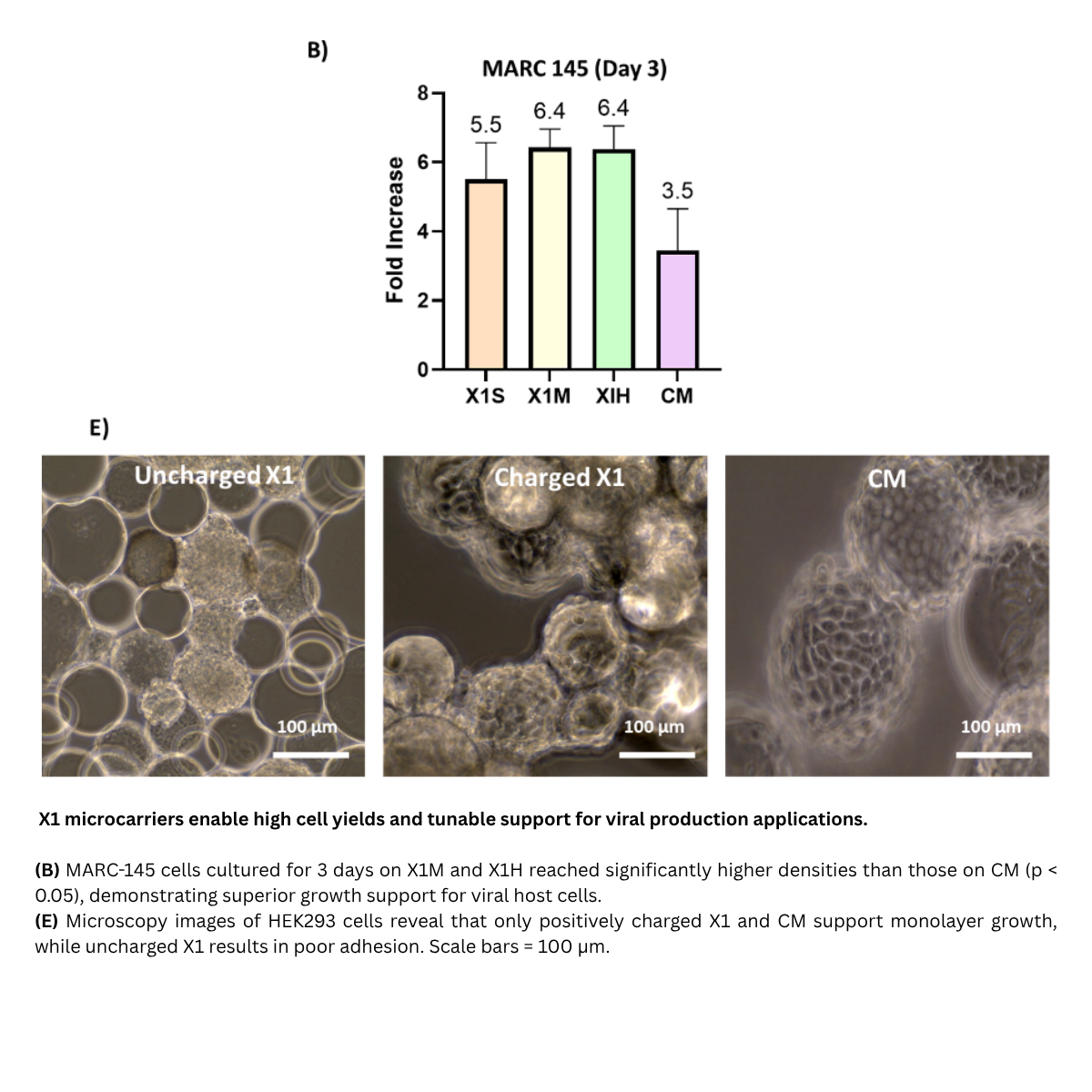

Vaccine & Viral Vector Production

Cell types:

- MARC-145 (monkey kidney cells for porcine vaccines)

- HEK293 (human embryonic kidney cells, widely used for viral vector production)

Key findings:

- Cell growth was ~2× higher on X1 MCs

- Final virus yield (TCID₅₀) was maintained or improved

- Stiffness adjustments allowed better control over cell clustering vs. spreading, helping optimise process conditions

Implication: For viral manufacturing platforms, X1 MCs support high-density growth without sacrificing viral output.

Summary of Advantages

| Feature | X1 Microcarriers | Traditional Commercial MCs |

| Customisable stiffness | ✅ Yes | ❌ No |

| Customisable surface charge | ✅ Yes | ❌ No |

| Dissolvable/harvest-friendly | ✅ Yes (TrypLE/enzymes) | ❌ No (requires filtration) |

| Edible & biodegradable | ✅ Yes | ❌ Often synthetic materials |

| Higher post-harvest recovery | ✅ Up to 93% | ❌ ~60% |

What This Means for the Industry

This research highlights a shift in how microcarriers are viewed, not as static components, but as tunable tools that can be tailored for specific cells and applications. The X1 platform demonstrates that mechanobiology (cell response to physical forces), when applied to microcarrier design, can directly improve outcomes.

Whether you’re in academia, biotech R&D, or scaling an industrial process, Smart MCs’ X1 microcarriers offer a flexible, high-performance solution for adherent cell culture.

Get in Touch

Interested in bringing X1 microcarriers into your workflow?

Whether you’re developing a new bioprocess, scaling up adherent cell cultures, or exploring high-performance platforms for cultivated meat, stem cells, or vaccine production… Smart MCs is here to help.

We offer:

- Custom microcarrier formulations tailored to your cell type and process

- Technical collaboration to support optimisation and integration

- Rapid turnaround for labs, startups, and manufacturers alike

📧 Email us: info@smartmcs.com.au

🌐 Learn more: www.smartmcs.com.au

Let’s build the future of cell manufacturing, together.

Citation

Cox, T. R., Lesmana, D., O’Keeffe, C. J., Lam, A., Zou, W., Lin, Z., Lin, X., Roberts, T. H., Lim, K. S., Oh, S. K. W., Radfar, P., Warkiani, M. E., & Ding, L. (2025). Maximising adherent cell production via customisable and dissolvable biopolymer microcarriers. Biomedical Materials, 20(4), 045005. https://doi.org/10.1088/1748-605X/adf1cd

Leave A Comment