Smart MCs, a biotech startup born out of the University of Technology Sydney (UTS) ecosystem, has been awarded an Accelerating Commercialisation government grant for their scaled up microcarrier production line, a project totalling $600K.

Smart MCs has been awarded the Accelerating Commercialisation Grant by the Australian Government to set up an automated microcarrier production line. The grant will allow Smart MCs to meet the rapidly increasing demand for our unique model of microcarriers, which are critical for scalable adherent cell culture in bioprocessing applications.

Accelerating Commercialisation (AC) Grants are awarded by The Australian Federal Government to businesses looking to commercialise a novel product, process or service to market. It needs to differ significantly to any previous innovations put to market by past applicants along with offering value and solutions to the respected field; in this case bioreactor-based cell culture. You can read more about AC grants through the Australian Government Website.

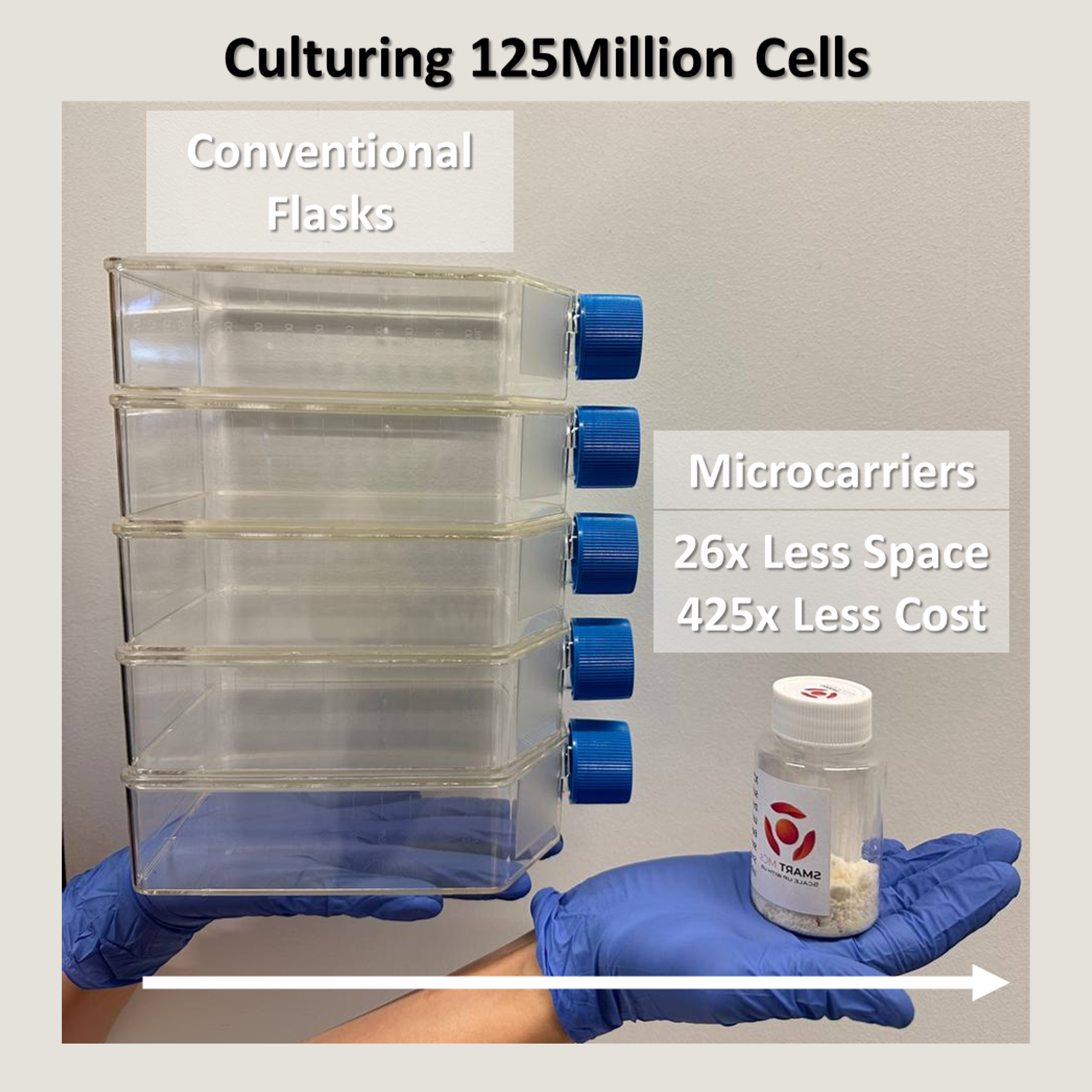

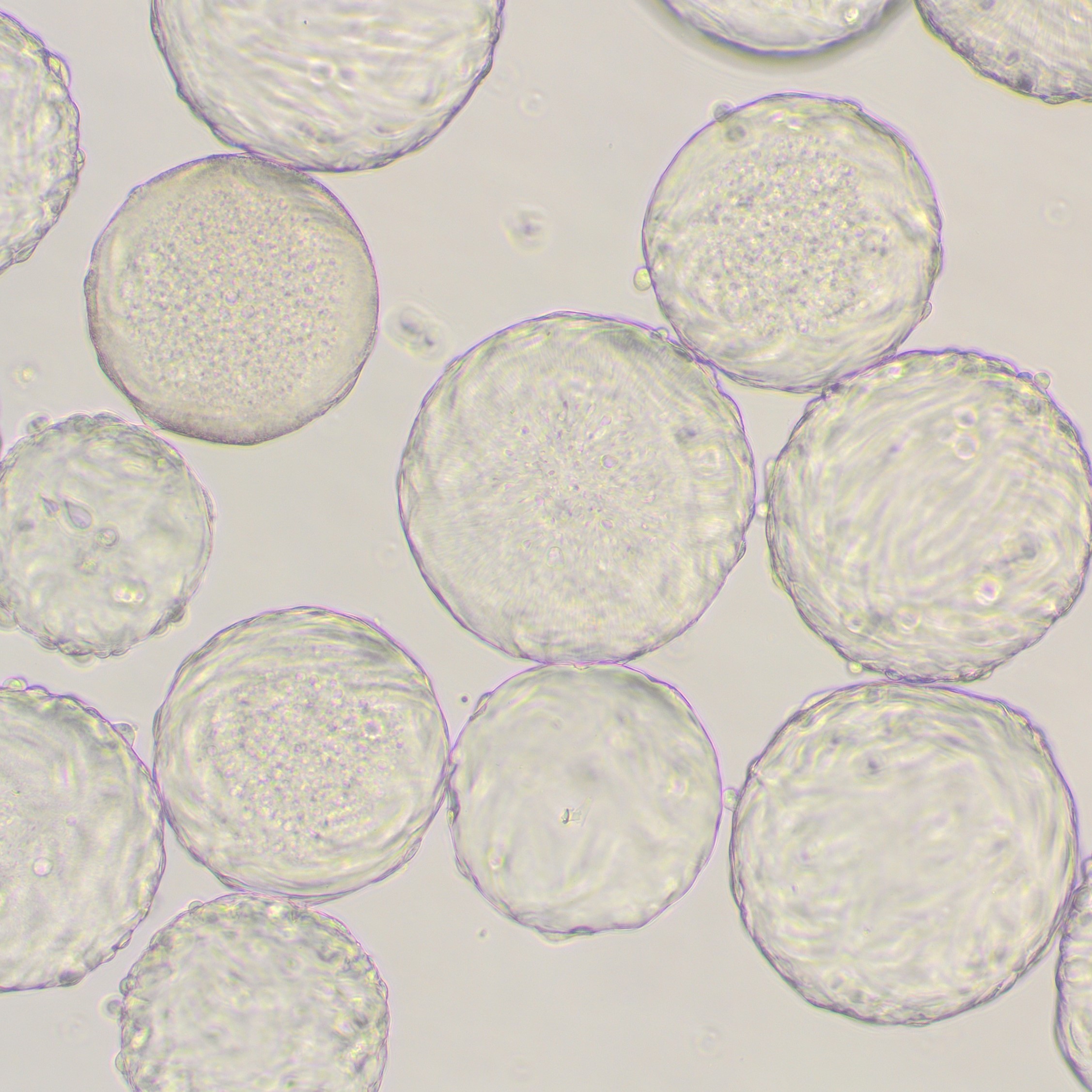

Conventional cell culture methods have been in operation for over 50 years, exhibiting a relatively common standardised design, which has shown limitations relating to concerns around particulates, residuals and breakages of carriers. Smart MCs’ unique microcarrier technology has been a breakthrough, with several customers now using our cell-type specific, biodegradable, and edible microcarriers in bioprocessing applications.

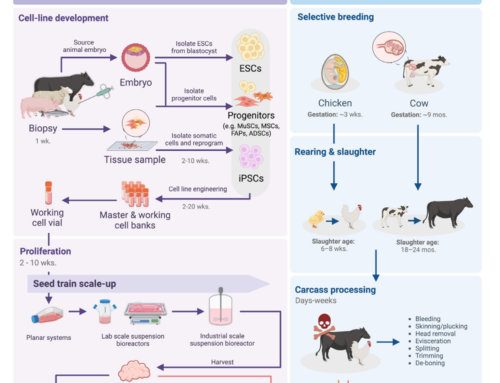

Microcarriers are micron-sized and spherical particles that provide a support structure for attachment, growth and differentiation of adherent cells inside bioreactors. Microcarriers are an important tool to scale up culture systems for industrial production of lab-grown meat or cellular therapies. – Read More on What are Microcarriers

The new facility enabled by the grant will facilitate Smart MCs to scale up microcarrier production immensely, matching the increasing demand from the bioprocessing industry for a more efficient and customisable microcarrier product. The biodegradable and edible materials used in these microcarriers eliminate inefficiencies and health concerns surrounding particulates and residuals or any breakage of carriers. Such applications of these customised microcarriers include exceedingly efficient and scalable production of stem cells and vaccines, along with cultured meat; an emerging food technology projected to see accelerated demand in the future. The automated production line will ensure consistent and reliable output of our microcarriers, along with significantly increasing the overall supply capacity of the company.

“We are excited to be awarded this grant by the Australian Government, which will allow us to take our microcarrier production to the next level and support the bioprocessing industry’s growth,” says Smart MCs CEO, Payar Radfar. “Our investment in this new production line will not only enable us to meet the rapidly growing demand for our products, but it will also allow us to play a crucial role in the development of the bioprocessing sector.”

The establishment of a fully automated microcarrier production line by Smart MCs is set to bring about significant change in the bioprocessing industry and enable the scalable production of adherent cell culture. The grant represents a milestone achievement for our company and reinforces our commitment to driving innovation in the bioprocessing sector.

For more information about Smart MCs and our microcarriers, see the rest of our Website here.

Leave A Comment