Publication Title: “High-Titer Manufacturing of SARS-CoV-2 Spike-Pseudotyped VSV in Stirred-Tank Bioreactors: A Leap in Vaccine Production Technology“.

DOI: 10.1016/j.omtm.2024.101189

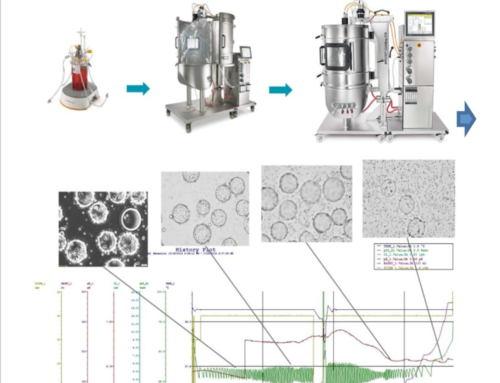

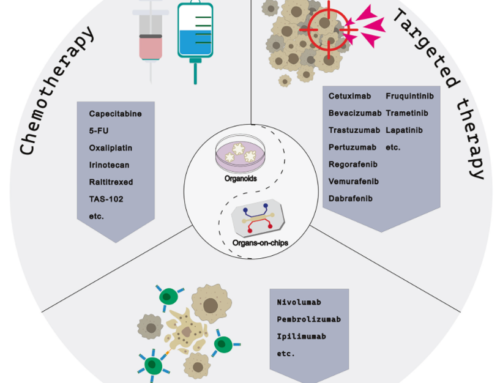

In a significant advancement for vaccine production technology, a recent article published in the journal of Methods & Clinical Development (Cell Press) has outlined the efficacy of microcarrier systems in stirred-tank bioreactors for the production of viral vectored vaccines. The research, entitled “High-titer manufacturing of SARS-CoV-2 spike-pseudotyped VSV in stirred-tank bioreactors” presents a novel approach to vaccine manufacturing, utilizing bioreactors in conjunction with various types of microcarriers. Notably, and in line with findings from Smart MCs, the study highlights that spherical microcarriers yield considerably higher output compared to other types.

In a significant advancement for vaccine production technology, a recent article published in the journal of Methods & Clinical Development (Cell Press) has outlined the efficacy of microcarrier systems in stirred-tank bioreactors for the production of viral vectored vaccines. The research, entitled “High-titer manufacturing of SARS-CoV-2 spike-pseudotyped VSV in stirred-tank bioreactors” presents a novel approach to vaccine manufacturing, utilizing bioreactors in conjunction with various types of microcarriers. Notably, and in line with findings from Smart MCs, the study highlights that spherical microcarriers yield considerably higher output compared to other types.

The Severe Acute Respiratory Syndrome Coronavirus 2 (SARS-CoV-2) pandemic has underscored the critical role of innovative vaccine development in public health. Since 2020, the rapid development of numerous vaccines, leveraging a variety of technological platforms, has been pivotal in combating SARS-CoV-2. However, a major challenge in the development of viral-vectored vaccines remains their manufacturing process.

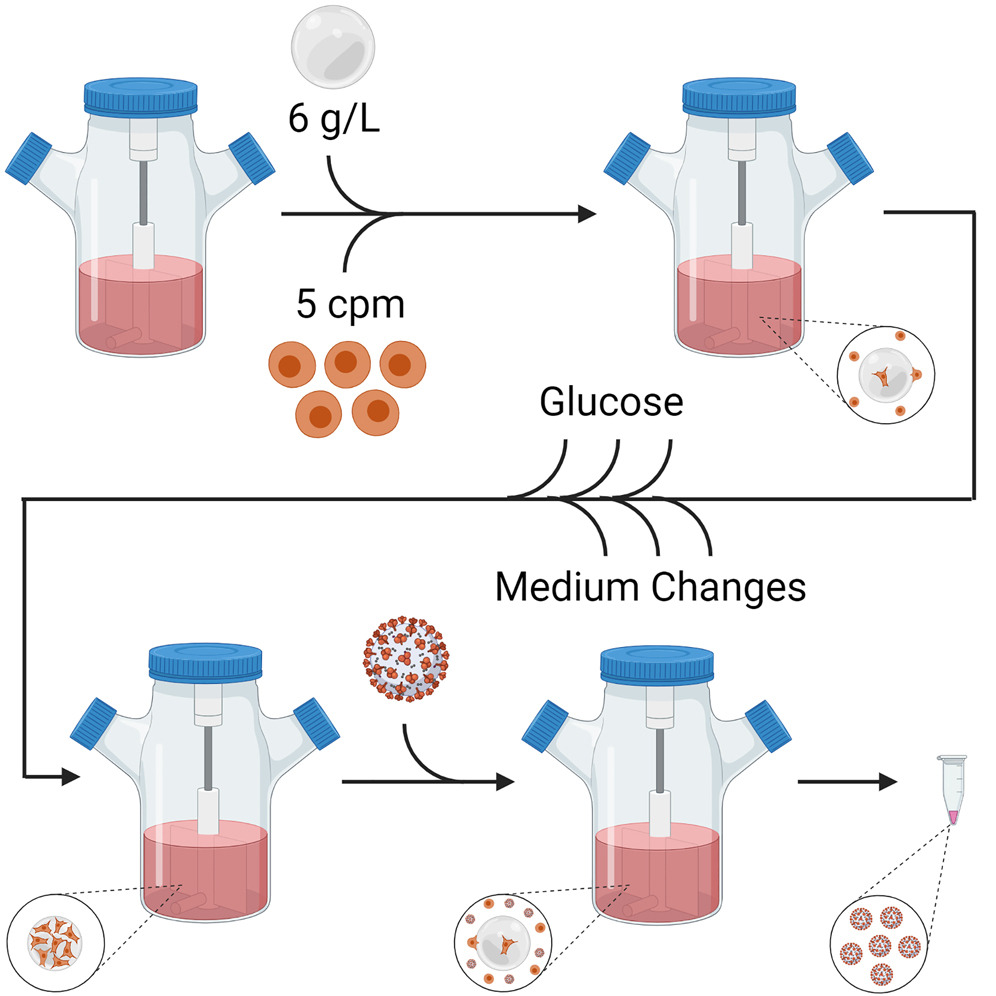

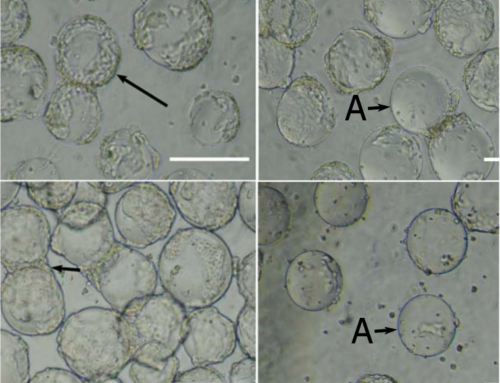

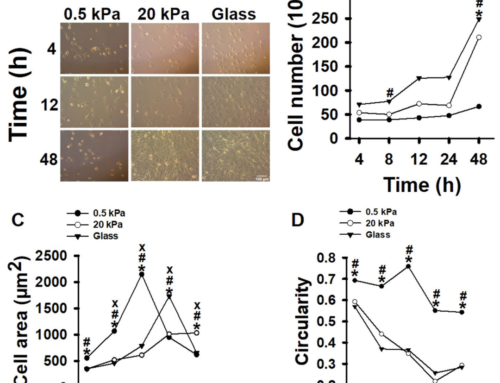

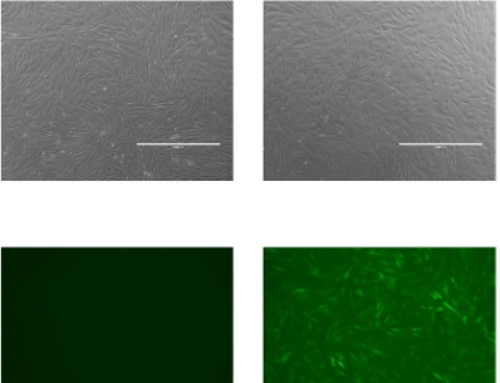

Addressing this challenge, the article details a scalable manufacturing protocol for replication-competent SARS-CoV-2 Spike-pseudotyped Vesicular Stomatitis Virus (S-VSV)-vectored vaccines. This method involves the use of Vero cells grown on microcarriers within a stirred-tank bioreactor. Through this approach, using Cytodex 1 microcarriers over a 6-day fed-batch culture period, Vero cells achieved a density of 3.95 + 0.42 × 10^6 cells/mL in 1 L stirred-tank bioreactors.

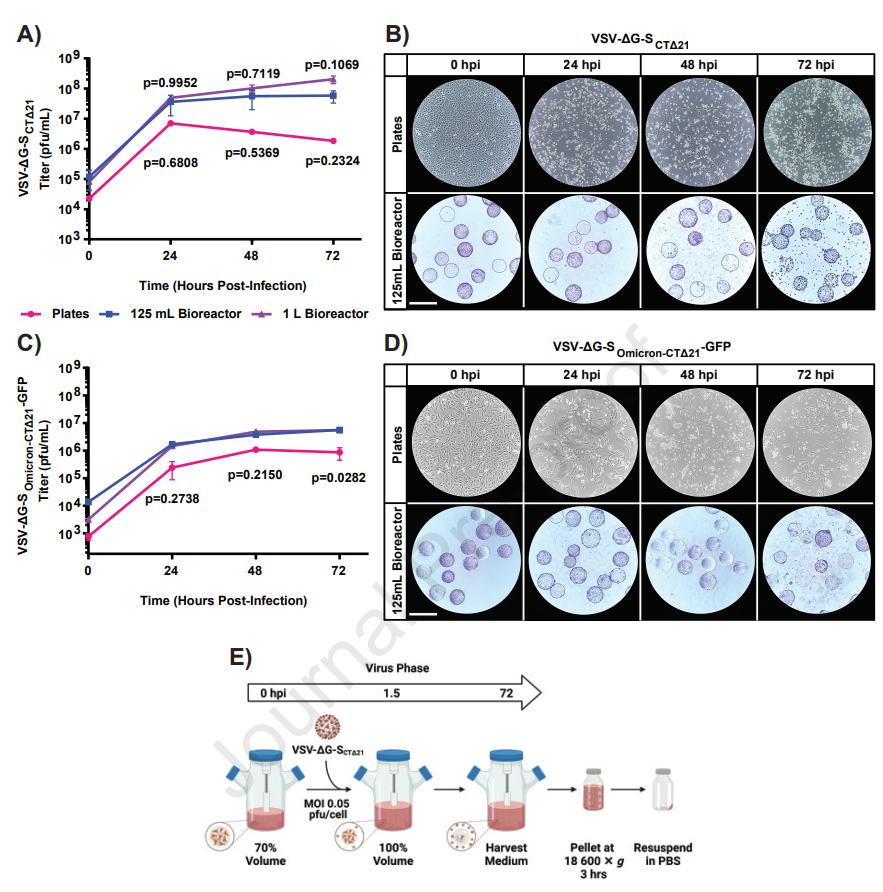

The study demonstrates a  remarkable efficiency in virus production. The ancestral strain of S-VSV attained a peak titer of 2.05 + 0.58 × 10^8 plaque-forming units (pfu)/mL at 3 days post-infection. This represents a 29-fold increase in virus production compared to plate-based cultures. To put it in perspective, a single 1 L bioreactor can produce the equivalent amount of virus as 1,284 15cm plates. Furthermore, the research also shows that the omicron BA.1 S-VSV reached a peak titer of 5.58 + 0.35 × 10^6 pfu/mL.

remarkable efficiency in virus production. The ancestral strain of S-VSV attained a peak titer of 2.05 + 0.58 × 10^8 plaque-forming units (pfu)/mL at 3 days post-infection. This represents a 29-fold increase in virus production compared to plate-based cultures. To put it in perspective, a single 1 L bioreactor can produce the equivalent amount of virus as 1,284 15cm plates. Furthermore, the research also shows that the omicron BA.1 S-VSV reached a peak titer of 5.58 + 0.35 × 10^6 pfu/mL.

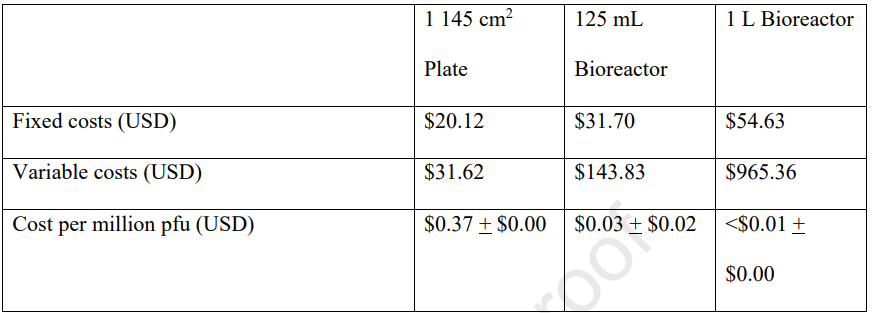

Furthermore, the cost analysis of these methods brings an additional layer of insight. The setup costs for each method were calculated to be $20 for the flask, $32 for the 125mL bioreactor, and $55 for the 1Litre bioreactor. However, when considering the cost per million PFU of virus produced, the larger bioreactors demonstrated exceptional cost-effectiveness. The flask, 125mL bioreactor, and 1Litre bioreactor incurred costs of $0.37, $0.03, and $0.01 per million PFU, respectively.

Quality control tests revealed that both plate- and bioreactor-produced S-VSV exhibited similar particle-to-pfu ratios. More importantly, they elicited comparable levels of neutralizing antibodies in immunized hamsters, indicating the effectiveness of the bioreactor-produced vaccines.

This breakthrough in vaccine manufacturing technology not only enhances the efficiency of producing viral vectored vaccines but also holds significant promise for rapid response in future pandemics. By enabling high-titer manufacturing of vaccines, this method could potentially streamline the vaccine development process, making it quicker and more cost-effective to meet global demands, especially during health crises.

The article serves as a testament to the ongoing innovations in the field of vaccine production and public health. As the world continues to face new health challenges, such advancements are crucial in ensuring timely and effective responses to emerging infectious diseases.

As we continue to explore the frontiers of vaccine manufacturing and production efficiency, Smart MCs stands ready to assist in the upscaling of viral production using adherent cells. Our unique microcarrier offerings are specifically designed to facilitate this process, ensuring both higher yields and cost-effectiveness. If you are interested in enhancing your viral production capabilities, get in touch with us to learn more about how we can provide tailored guidance and support for the scale-up of your viral production needs. Our team at Smart MCs is dedicated to empowering your scientific endeavors with cutting-edge solutions. Get in Touch for More Information

Leave A Comment